Operation Breakdown of Swim Short

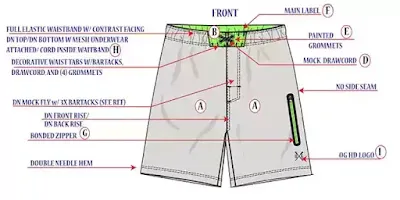

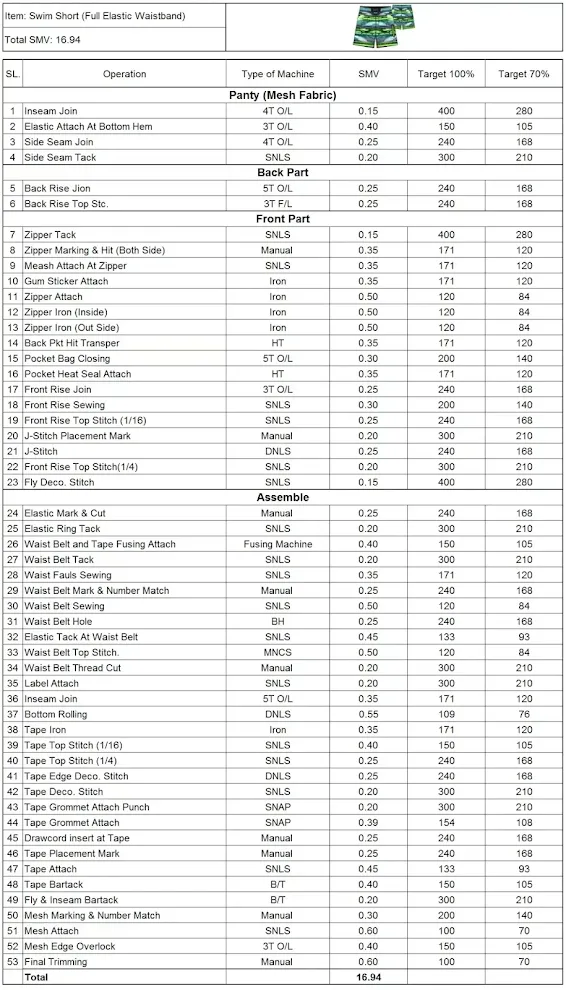

This swim short is easy to prepare the layout. You may face problem to attach sticker which is surrounded the zipper. In my industrial engineering tutorial series, I am sharing an operation breakdown of Swim Short. You can refer to this operation bulletin to learn about various operations involved and machine requirements in making swim short or swim trunk. I describe the operation breakdown of Swim Short (Full Elastic Waistband). It is also known as swim trunk.

Operation Breakdown of Swim Short

Operation Breakdown of Swim Short is done by

the following table. It is also known as an operation

bulletin of swim short. In this operation bulletin process list, estimated

time, machine name, hourly production target quantity at 100% and 70%

efficiency are shown. The estimated time (SMV) shown in the below table will

vary according to the product method followed and machine and equipment used in

actual production. So please be careful while you use the above estimated time

against each operation.

How to join Swim Short inner part and outer part at waistband?

Mash attach with Shell Part | Waistband Side.

In this detailed tutorial, learn how to attach a mash to a shell part at the waistband side. Perfect for sewing enthusiasts and professionals looking to perfect their techniques. Follow step-by-step instructions to achieve a clean and durable finish. Don't forget to like, share, and subscribe for more sewing tutorials.

Operation Breakdown of Swim Short

|

SL. |

Operation |

Type of Machine |

SMV |

Target 100% |

Target 70% |

|

Panty (Mesh Fabric) |

|||||

|

1 |

Inseam Join |

4T O/L |

0.15 |

400 |

280 |

|

2 |

Elastic Attach At Bottom Hem |

3T O/L |

0.40 |

150 |

105 |

|

3 |

Side Seam Join |

4T O/L |

0.25 |

240 |

168 |

|

4 |

Side Seam Tack |

SNLS |

0.20 |

300 |

210 |

|

Back Part |

|||||

|

5 |

Back Rise Jion |

5T O/L |

0.25 |

240 |

168 |

|

6 |

Back Rise Top Stc. |

3T F/L |

0.25 |

240 |

168 |

|

Front Part |

|||||

|

7 |

Zipper Tack |

SNLS |

0.15 |

400 |

280 |

|

8 |

Zipper Marking & Hit (Both

Side) |

Manual |

0.35 |

171 |

120 |

|

9 |

Mesh Attach At Zipper |

SNLS |

0.35 |

171 |

120 |

|

10 |

Gum Sticker Attach |

Iron |

0.35 |

171 |

120 |

|

11 |

Zipper Attach |

Iron |

0.50 |

120 |

84 |

|

12 |

Zipper Iron (Inside) |

Iron |

0.50 |

120 |

84 |

|

13 |

Zipper Iron (Out Side) |

Iron |

0.50 |

120 |

84 |

|

14 |

Back Pkt Hit |

HT |

0.35 |

171 |

120 |

|

15 |

Pocket Bag Closing |

5T O/L |

0.30 |

200 |

140 |

|

16 |

Pocket Heat Seal Attach |

HT |

0.35 |

171 |

120 |

|

17 |

Front Rise Join |

3T O/L |

0.25 |

240 |

168 |

|

18 |

Front Rise Sewing |

SNLS |

0.30 |

200 |

140 |

|

19 |

Front Rise Top Stitch (1/16) |

SNLS |

0.25 |

240 |

168 |

|

20 |

J-Stitch Placement Mark |

Manual |

0.20 |

300 |

210 |

|

21 |

J-Stitch |

DNLS |

0.25 |

240 |

168 |

|

22 |

Front Rise Top Stitch(1/4) |

SNLS |

0.20 |

300 |

210 |

|

23 |

Fly Decoration Stitch |

SNLS |

0.15 |

400 |

280 |

|

Assemble |

|||||

|

24 |

Elastic Mark & Cut |

Manual |

0.25 |

240 |

168 |

|

25 |

Elastic Ring Tack |

SNLS |

0.20 |

300 |

210 |

|

26 |

Waist Belt and Tape Fusing Attach |

Fusing Machine |

0.40 |

150 |

105 |

|

27 |

Waist Belt Tack |

SNLS |

0.20 |

300 |

210 |

|

28 |

Waist Fauls Sewing |

SNLS |

0.35 |

171 |

120 |

|

29 |

Waist Belt Mark & Number Match |

Manual |

0.25 |

240 |

168 |

|

30 |

Waist Belt Sewing |

SNLS |

0.50 |

120 |

84 |

|

31 |

Waist Belt Hole |

BH |

0.25 |

240 |

168 |

|

32 |

Elastic Tack at Waist Belt |

SNLS |

0.45 |

133 |

93 |

|

33 |

Waist Belt Top Stitch. |

MNCS |

0.50 |

120 |

84 |

|

34 |

Waist Belt Thread Cut |

Manual |

0.20 |

300 |

210 |

|

35 |

Label Attach |

SNLS |

0.20 |

300 |

210 |

|

36 |

Inseam Join |

5T O/L |

0.35 |

171 |

120 |

|

37 |

Bottom Rolling |

DNLS |

0.55 |

109 |

76 |

|

38 |

Tape Iron |

Iron |

0.35 |

171 |

120 |

|

39 |

Tape Top Stitch (1/16) |

SNLS |

0.40 |

150 |

105 |

|

40 |

Tape Top Stitch (1/4) |

SNLS |

0.25 |

240 |

168 |

|

41 |

Tape Edge Decoration Stitch |

DNLS |

0.25 |

240 |

168 |

|

42 |

Tape Decoration Stitch |

SNLS |

0.20 |

300 |

210 |

|

43 |

Tape Grommet Attach Punch |

SNAP |

0.20 |

300 |

210 |

|

44 |

Tape Grommet Attach |

SNAP |

0.39 |

154 |

108 |

|

45 |

Draw-cord insert at Tape |

Manual |

0.25 |

240 |

168 |

|

46 |

Tape Placement Mark |

Manual |

0.25 |

240 |

168 |

|

47 |

Tape Attach |

SNLS |

0.45 |

133 |

93 |

|

48 |

Tape Bartack |

B/T |

0.40 |

150 |

105 |

|

49 |

Fly & Inseam Bartack |

B/T |

0.20 |

300 |

210 |

|

50 |

Mesh Marking & Number Match |

Manual |

0.30 |

200 |

140 |

|

51 |

Mesh Attach |

SNLS |

0.60 |

100 |

70 |

|

52 |

Mesh Edge Overlock |

3T O/L |

0.40 |

150 |

105 |

|

53 |

Final Trimming |

Manual |

0.60 |

100 |

70 |

|

|

Total |

|

16.94 |

|

|

In the above table a short name of sewing machines is written. Followings are the abbreviation of those short machine codes.

DNLS - Double needle lock stitch

Snap - Snap button attaching machine

MNCS - Multi needle chain stitch

3T O/L - 3 Thread over lock

4T O/L - 4 Thread over lock

5T O/L - 5 Thread over lock

Heat-seal - Heat-seal Machine

B/T - Bartack

Manual - Helper

Thank you to read my post. Please, share this article with others. If you any suggestion of this content let me know in the comment.

Excellent information. Thanks

ReplyDeleteGood initiative. Thanks a lot

ReplyDelete