What is operation breakdown in the garment industry?

A breakdown is a list of things that work by elements in the apparel industry by industrial engineering. One garment consists of some parts and by number of stitching and non stitching activities. Breakdown means writing down all the parts and all the processes or operations one after another to complete the garment and type of machines to each and every process.

Importance of operation breakdown:

- To understand garment construction - like type of stitch/seam, type of machine.

- To prepare an operation bulletin the first step is doing operation breakdown of the garment.

- Requirement of sewing machines and equipment to make the garment.

- Requirement of worker to make the garment.

- To learn about additional guides, folders and attachments

- Operation breakdown reduces our unnecessary work and time

- Operation breakdown is followed by sewing floor management

Advantages of Operation Breakdown:

- We can see all the activities of the garments at once.

- We can predict the difficulties of performing critical operations

- We can create the layout in a simple, easy and less time consuming way

- We can easily choose the right operator for the right process.

- We can easily select the correct method for the process.

- We will know the quantity and types of machines for making the required

- garments according to the target plan.

Operation breakdown method:

- The floor management (executive, technician and work-study officer) shouldsit together to make the breakdown.

- Technician assembles the broken parts one by one.

- Then the work-study officer writes down the SMV of those operations

- and take the approval.

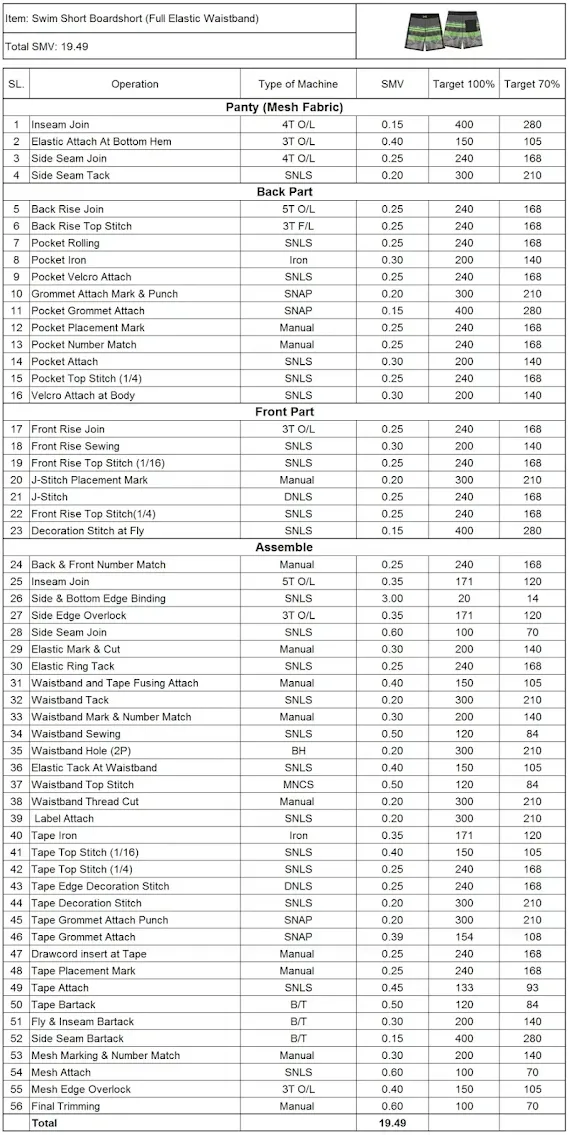

The operations are written in sequence of the actual process flows to make the garment layout for the line/floor. One sample operation breakdown of swim short is shown in the below:

Formula to set the 100% target:

Target per hour= (Worker x Working hour x 60/ SMV) x efficiency %

Basic Pitch Time (BPT) =Total SMV / Total Manpower

In an operation breakdown, we listed the different parts and components of the garment, sewing and machine types and the labor required to make the garment. It helps us to increase productivity and efficiency.

You Might Find Useful Related to Industrial Engineering:

- 24 Effective Ways to Improve Productivity in Garment Production.

- Productivity Improve in Garments Industry.

- What is Assort Called in Garment Industry?

- Technical audit in the garment industry.

- What is sewing needle in the garment industry?

- What is 5S in the garment industry?

- What is garment sample in garments Factory?

- Difference between TQM and QMS.

- How to solve bottleneck problem in the Garment Industry?

- Productivity improvement factors in garment industries.

- Various Types of Industrial Sewing Machines.

- Industrial Engineering (IE) in Garment Industry.

- How to calculate productivity in the garments?

Thanks for reading my post. Please share my post to others. It will inspire me to write down more about Garments Related Topics.

Thanks for your helpful post

ReplyDeleteNice post. Thanks

ReplyDeletenice

ReplyDelete