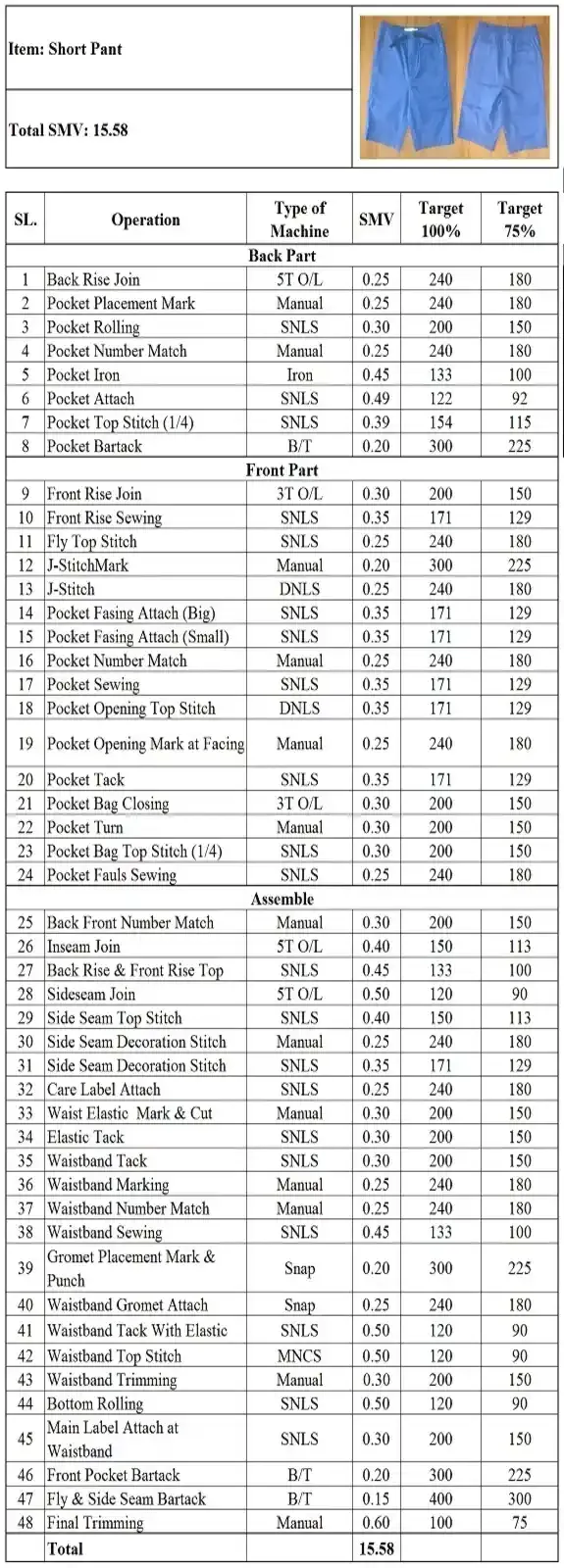

Operation Breakdown of Short Pant

Operation Breakdown of Short Pant

|

SL. |

Operation |

Type of Machine |

SMV |

Target 100% |

Target 75% |

|

Back Part |

|||||

|

1 |

Back Rise Join |

5T O/L |

0.25 |

240 |

180 |

|

2 |

Pocket Placement Mark |

Manual |

0.25 |

240 |

180 |

|

3 |

Pocket Rolling |

SNLS |

0.30 |

200 |

150 |

|

4 |

Pocket Number Match |

Manual |

0.25 |

240 |

180 |

|

5 |

Pocket Iron |

Iron |

0.45 |

133 |

100 |

|

6 |

Pocket Attach |

SNLS |

0.49 |

122 |

92 |

|

7 |

Pocket Top Stitch (1/4) |

SNLS |

0.39 |

154 |

115 |

|

8 |

Pocket Bartack |

B/T |

0.20 |

300 |

225 |

|

Front Part |

|||||

|

9 |

Front Rise Join |

3T O/L |

0.30 |

200 |

150 |

|

10 |

Front Rise Sewing |

SNLS |

0.35 |

171 |

129 |

|

11 |

Fly Top Stitch |

SNLS |

0.25 |

240 |

180 |

|

12 |

J-Stitch Mark |

Manual |

0.20 |

300 |

225 |

|

13 |

J-Stitch |

DNLS |

0.25 |

240 |

180 |

|

14 |

Pocket Facing Attach (Big) |

SNLS |

0.35 |

171 |

129 |

|

15 |

Pocket Facing Attach (Small) |

SNLS |

0.35 |

171 |

129 |

|

16 |

Pocket Number Match |

Manual |

0.25 |

240 |

180 |

|

17 |

Pocket Sewing |

SNLS |

0.35 |

171 |

129 |

|

18 |

Pocket Opening Top Stitch |

DNLS |

0.35 |

171 |

129 |

|

19 |

Pocket Opening Mark at Facing |

Manual |

0.25 |

240 |

180 |

|

20 |

Pocket Tack |

SNLS |

0.35 |

171 |

129 |

|

21 |

Pocket Bag Closing |

3T O/L |

0.30 |

200 |

150 |

|

22 |

Pocket Turn |

Manual |

0.30 |

200 |

150 |

|

23 |

Pocket Bag Top Stitch (1/4) |

SNLS |

0.30 |

200 |

150 |

|

24 |

Pocket Fauls Sewing |

SNLS |

0.25 |

240 |

180 |

|

Assemble |

|||||

|

25 |

Back Front Number Match |

Manual |

0.30 |

200 |

150 |

|

26 |

Inseam Join |

5T O/L |

0.40 |

150 |

113 |

|

27 |

Back Rise & Front Rise Top

Stitch |

SNLS |

0.45 |

133 |

100 |

|

28 |

Side seam Join |

5T O/L |

0.50 |

120 |

90 |

|

29 |

Side Seam Top Stitch |

SNLS |

0.40 |

150 |

113 |

|

30 |

Side Seam Decoration Stitch Mark |

Manual |

0.25 |

240 |

180 |

|

31 |

Side Seam Decoration Stitch (1/4) |

SNLS |

0.35 |

171 |

129 |

|

32 |

Care Label Attach |

SNLS |

0.25 |

240 |

180 |

|

33 |

Waist Elastic Mark & Cut |

Manual |

0.30 |

200 |

150 |

|

34 |

Elastic Tack |

SNLS |

0.30 |

200 |

150 |

|

35 |

Waistband Tack |

SNLS |

0.30 |

200 |

150 |

|

36 |

Waistband Marking |

Manual |

0.25 |

240 |

180 |

|

37 |

Waistband Number Match |

Manual |

0.25 |

240 |

180 |

|

38 |

Waistband Sewing |

SNLS |

0.45 |

133 |

100 |

|

39 |

Grommet Placement Mark & Punch |

Snap |

0.20 |

300 |

225 |

|

40 |

Waistband Grommet Attach |

Snap |

0.25 |

240 |

180 |

|

41 |

Waistband Tack With Elastic |

SNLS |

0.50 |

120 |

90 |

|

42 |

Waistband Top Stitch |

MNCS |

0.50 |

120 |

90 |

|

43 |

Waistband Trimming |

Manual |

0.30 |

200 |

150 |

|

44 |

Bottom Rolling |

SNLS |

0.50 |

120 |

90 |

|

45 |

Main Label Attach at Waistband |

SNLS |

0.30 |

200 |

150 |

|

46 |

Front Pocket Bartack |

B/T |

0.20 |

300 |

225 |

|

47 |

Fly & Side Seam Bartack |

B/T |

0.15 |

400 |

300 |

|

48 |

Final Trimming |

Manual |

0.60 |

100 |

75 |

|

|

Total |

|

15.58 |

|

|

Full form of Machine Name:

SNLS - Single needle lock stitch

DNLS - Double needle lock stitch

MNCS - Multi needle Chain stitch

3T O/L - 3 Thread over lock

5T O/L - 5 Thread over lock

Snap - Snap Machine

BT - Bartack

Manual - Helper

How to set the target per hour in the Sewing line of the Garment Factory?

It will be best to set the line layout target based on line efficiency, line cost and delivery date of style.

Formula to set the 100% target:

Daily Target = (Worker x Working hour x 60/ SMV) x efficiency %

Basic Pitch Time (BPT) =Total SMV / Total Manpower

Fabric Types and Needle Size Chart:

|

Fabric Types |

Needle Size |

|

Very fine fabrics (silk, chiffon,

organza, voile, lace) |

8, 9, 10 |

|

Light weight fabrics (cotton,

heavier silks, synthetics, spandex, lycra) |

11, 12 |

Operation Bulletin makes our work easy to set up a production line in the apparel industry. We can easily manage machine and operator requirements for any sewing line by this. But it is necessary to do an operation breakdown to prepare a machine layout and line balancing by industrial engineering (IE).

No comments

Please let me know if anything needs to be added