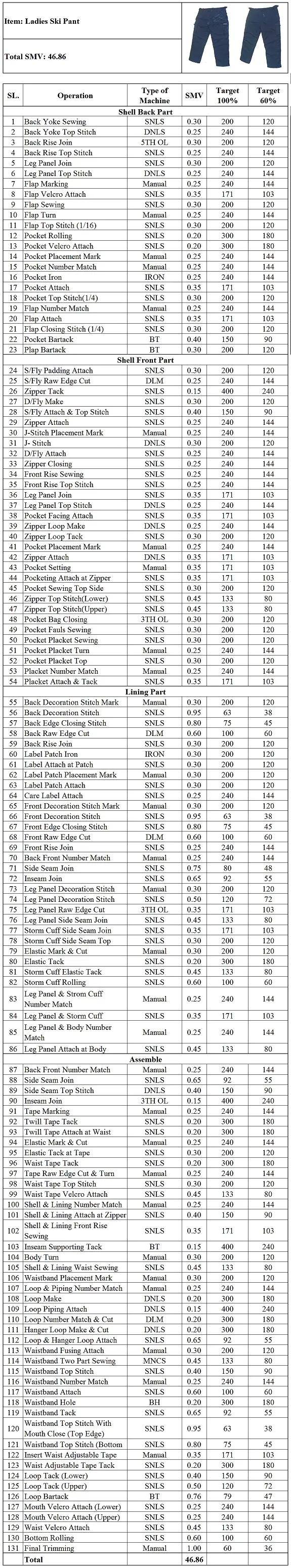

Operation Bulletin of Ladies Ski Pant

In my industrial engineering tutorial series, I am sharing an Operation Bulletin of Ladies Ski Pant. You can refer to this operation bulletin to learn about various operations involved, SMV and machine requirements in making Ladies Ski Pant.

A Ladies Ski Pant is a critical style to produce in the sewing line. It has lots of complex processes. Here I describe the operation breakdown of the Vest with SMV and Machine names.

Operation Bulletin of Ladies Ski Pant is done by the following table. In this operation bulletin process list, estimated time, machine name, hourly production target quantity at 100% and 60% efficiency are shown. The estimated time (SMV) shown in the below table will vary according to the product method followed and machine and equipment used in actual production. So please be careful while you use the above estimated time against each operation.

Operation Bulletin of Ladies Ski Pant

SL.

Operation

Type of Machine

SMV

Target 100%

Target 60%

Shell Back Part

1

Back Yoke Sewing

SNLS

0.30

200

120

2

Back Yoke Top Stitch

DNLS

0.25

240

144

3

Back Rise Join

5TH OL

0.30

200

120

4

Back Rise Top Stitch

SNLS

0.25

240

144

5

Leg Panel Join

SNLS

0.30

200

120

6

Leg Panel Top Stitch

DNLS

0.25

240

144

7

Flap Marking

Manual

0.25

240

144

8

Flap Velcro Attach

SNLS

0.35

171

103

9

Flap Sewing

SNLS

0.30

200

120

10

Flap Turn

Manual

0.25

240

144

11

Flap Top Stitch (1/16)

SNLS

0.30

200

120

12

Pocket Rolling

SNLS

0.20

300

180

13

Pocket Velcro Attach

SNLS

0.20

300

180

14

Pocket Placement Mark

Manual

0.25

240

144

15

Pocket Number Match

Manual

0.25

240

144

16

Pocket Iron

IRON

0.25

240

144

17

Pocket Attach

SNLS

0.35

171

103

18

Pocket Top Stitch (1/4)

SNLS

0.30

200

120

19

Flap Number Match

Manual

0.25

240

144

20

Flap Attach

SNLS

0.35

171

103

21

Flap Closing Stitch (1/4)

SNLS

0.30

200

120

22

Pocket Bartack

BT

0.40

150

90

23

Flap Bartack

BT

0.30

200

120

Shell Front Part

24

S/Fly Padding Attach

SNLS

0.30

200

120

25

S/Fly Raw Edge Cut

DLM

0.25

240

144

26

Zipper Tack

SNLS

0.15

400

240

27

Double Fly Make

SNLS

0.30

200

120

28

S/Fly Attach & Top Stitch

SNLS

0.40

150

90

29

Zipper Attach

SNLS

0.25

240

144

30

J-Stitch Placement Mark

Manual

0.25

240

144

31

J- Stitch

DNLS

0.30

200

120

32

Double Fly Attach

SNLS

0.25

240

144

33

Zipper Closing

SNLS

0.25

240

144

34

Front Rise Sewing

SNLS

0.25

240

144

35

Front Rise Top Stitch

SNLS

0.25

240

144

36

Leg Panel Join

SNLS

0.35

171

103

37

Leg Panel Top Stitch

DNLS

0.25

240

144

38

Pocket Facing Attach

SNLS

0.35

171

103

39

Zipper Loop Make

DNLS

0.25

240

144

40

Zipper Loop Tack

SNLS

0.30

200

120

41

Pocket Placement Mark

Manual

0.25

240

144

42

Zipper Attach

DNLS

0.35

171

103

43

Pocket Setting

Manual

0.35

171

103

44

Pocketing Attach at Zipper

SNLS

0.35

171

103

45

Pocket Sewing Top Side

SNLS

0.30

200

120

46

Zipper Top Stitch (Lower)

SNLS

0.45

133

80

47

Zipper Top Stitch (Upper)

SNLS

0.45

133

80

48

Pocket Bag Closing

3TH OL

0.30

200

120

49

Pocket Fauls Sewing

SNLS

0.30

200

120

50

Pocket Placket Sewing

SNLS

0.30

200

120

51

Pocket Placket Turn

Manual

0.25

240

144

52

Pocket Placket Top Stitch (1/16)

SNLS

0.30

200

120

53

Placket Number Match

Manual

0.25

240

144

54

Placket Attach & Tack

SNLS

0.35

171

103

Lining Part

55

Back Decoration Stitch Mark

Manual

0.30

200

120

56

Back Decoration Stitch

SNLS

0.95

63

38

57

Back Edge Closing Stitch

SNLS

0.80

75

45

58

Back Raw Edge Cut

DLM

0.60

100

60

59

Back Rise Join

SNLS

0.30

200

120

60

Label Patch Iron

IRON

0.30

200

120

61

Label Attach at Patch

SNLS

0.30

200

120

62

Label Patch Placement Mark

Manual

0.30

200

120

63

Label Patch Attach

SNLS

0.30

200

120

64

Care Label Attach

SNLS

0.25

240

144

65

Front Decoration Stitch Mark

Manual

0.30

200

120

66

Front Decoration Stitch

SNLS

0.95

63

38

67

Front Edge Closing Stitch

SNLS

0.80

75

45

68

Front Raw Edge Cut

DLM

0.60

100

60

69

Front Rise Join

SNLS

0.25

240

144

70

Back Front Number Match

Manual

0.25

240

144

71

Side Seam Join

SNLS

0.75

80

48

72

Inseam Join

SNLS

0.65

92

55

73

Leg Panel Decoration Stitch Mark

Manual

0.30

200

120

74

Leg Panel Decoration Stitch

SNLS

0.50

120

72

75

Leg Panel Raw Edge Cut

3TH OL

0.35

171

103

76

Leg Panel Side Seam Join

SNLS

0.45

133

80

77

Storm Cuff Side Seam Join

SNLS

0.35

171

103

78

Storm Cuff Side Seam Top Stitch (1/4)

SNLS

0.30

200

120

79

Elastic Mark & Cut

Manual

0.30

200

120

80

Elastic Tack

SNLS

0.20

300

180

81

Storm Cuff Elastic Tack

SNLS

0.45

133

80

82

Storm Cuff Rolling

SNLS

0.60

100

60

83

Leg Panel & Storm Cuff Number Match

Manual

0.25

240

144

84

Leg Panel & Storm Cuff Sewing

SNLS

0.35

171

103

85

Leg Panel & Body Number Match

Manual

0.25

240

144

86

Leg Panel Attach at Body

SNLS

0.45

133

80

Assemble

87

Back Front Number Match

Manual

0.25

240

144

88

Side Seam Join

SNLS

0.65

92

55

89

Side Seam Top Stitch

DNLS

0.40

150

90

90

Inseam Join

3TH OL

0.15

400

240

91

Tape Marking

Manual

0.25

240

144

92

Twill Tape Tack

SNLS

0.20

300

180

93

Twill Tape Attach at Waist Tape

SNLS

0.20

300

180

94

Elastic Mark & Cut

Manual

0.25

240

144

95

Elastic Tack at Tape

SNLS

0.30

200

120

96

Waist Tape Tack

SNLS

0.20

300

180

97

Tape Raw Edge Cut & Turn

Manual

0.25

240

144

98

Waist Tape Top Stitch

SNLS

0.30

200

120

99

Waist Tape Velcro Attach

SNLS

0.45

133

80

100

Shell & Lining Number Match

Manual

0.25

240

144

101

Shell & Lining Attach at Zipper

SNLS

0.40

150

90

102

Shell & Lining Front Rise Sewing

SNLS

0.35

171

103

103

Inseam Supporting Tack

BT

0.15

400

240

104

Body Turn

Manual

0.30

200

120

105

Shell & Lining Waist Sewing

SNLS

0.45

133

80

106

Waistband Placement Mark

Manual

0.30

200

120

107

Loop & Piping Number Match

Manual

0.25

240

144

108

Loop Make

DNLS

0.20

300

180

109

Loop Piping Attach

DNLS

0.15

400

240

110

Loop Number Match & Cut

DLM

0.20

300

180

111

Hanger Loop Make & Cut

DNLS

0.20

300

180

112

Loop & Hanger Loop Attach

SNLS

0.65

92

55

113

Waistband Fusing Attach

Manual

0.30

200

120

114

Waistband Two Part Sewing

MNCS

0.45

133

80

115

Waistband Top Stitch

SNLS

0.40

150

90

116

Waistband Number Match

Manual

0.25

240

144

117

Waistband Attach

SNLS

0.60

100

60

118

Waistband Hole

BH

0.20

300

180

119

Waistband Tack

SNLS

0.65

92

55

120

Waistband Top Stitch With Mouth Close (Top Edge)

SNLS

0.95

63

38

121

Waistband Top Stitch (Bottom Edge)

SNLS

0.80

75

45

122

Insert Waist Adjustable Tape

Manual

0.35

171

103

123

Waist Adjustable Tape Tack

SNLS

0.20

300

180

124

Loop Tack (Lower)

SNLS

0.40

150

90

125

Loop Tack (Upper)

SNLS

0.50

120

72

126

Loop Bartack

BT

0.76

79

47

127

Mouth Velcro Attach (Lower)

SNLS

0.25

240

144

128

Mouth Velcro Attach (Upper)

SNLS

0.25

240

144

129

Waist Velcro Attach

SNLS

0.45

133

80

130

Bottom Rolling

SNLS

0.60

100

60

131

Final Trimming

Manual

1.00

60

36

Total

46.86

Full form of Machine Name:

In the above table a short name of sewing machines is written. Followings are the abbreviation of those short machine codes.

- SNLS - Single needle lock stitch

- DNLS - Double needle lock stitch

- DLM - Single needle edge cutter machine

- 3T O/L - 3 Thread over lock

- MNCS - Kansai Machine

- BT - Bartack Machine

- BH - Button Hole Machine

- Manual - Helper

Formula to set the 100% target:

Daily Target = (Worker x Working hour x 60/ SMV) x efficiency %

Basic Pitch Time (BPT) =Total SMV / Total Manpower

We can use “Ball Point or Sharp Point" Needle to stitch this item.

Fabric Types and Needle Size Chart:

Operation Bulletin makes our work easy to set up a production line in the apparel industry. We can easily manage machine and operator requirements for any sewing line by this. But it is necessary to do an operation breakdown to prepare a machine layout and line balancing by industrial engineering (IE).

Do you want to learn more about "what is operation breakdown?" You can visit my post to learn more about bulletin or breakdown of garments in the garment industry. You can find the Operation Breakdown of Swim Short here.

Thank you for your patience reading my blog post. Please, Share this article with others. It will inspire me to write more about this. Please keep in touch with my page to know the update.

“Wear a mask to save lives. Clean your hands. Keep at a safe distance.”

Nice post

ReplyDelete