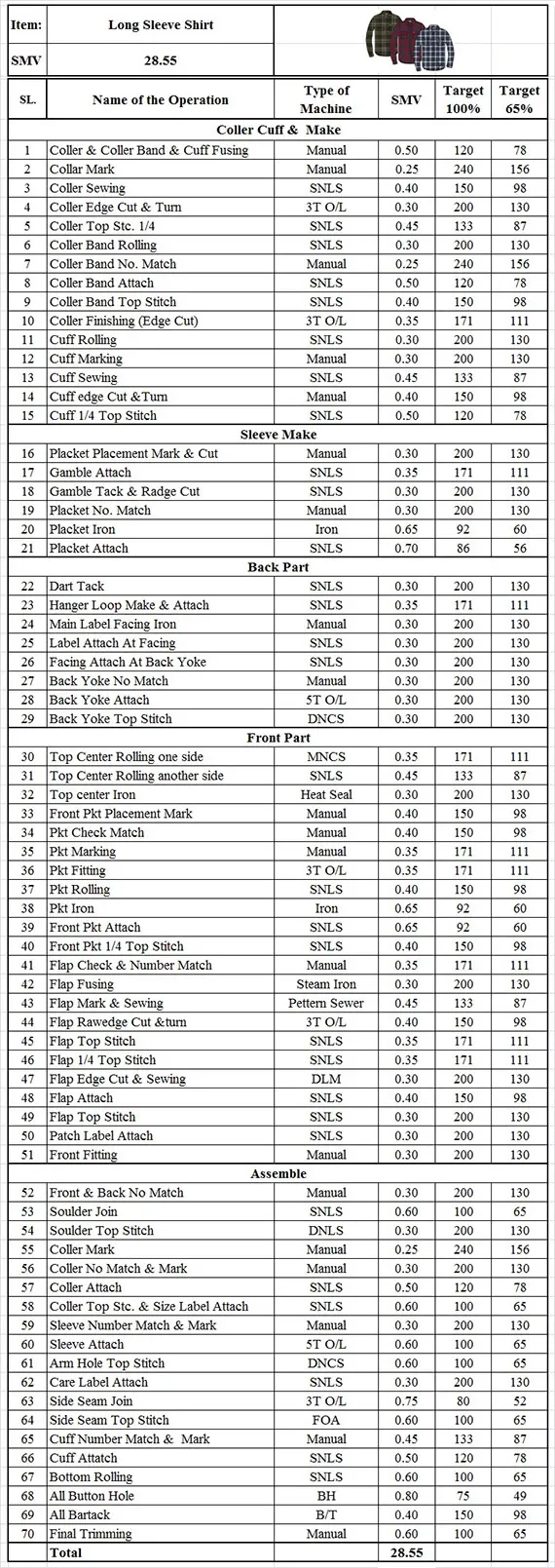

Operation Breakdown of a Long Sleeve Check Shirt

Operation Breakdown of a Long Sleeve Check Shirt

|

Item: |

Long Sleeve Check Shirt |

||||

|

SMV |

28.55 |

|

|

|

|

|

SL. |

Name of the Operation |

Type of Machine |

SMV |

Target 100% |

Target 65% |

|

Collar Cuff &

Make |

|||||

|

1 |

Collar & Collar

Band & Cuff Fusing |

Manual |

0.50 |

120 |

78 |

|

2 |

Collar Mark |

Manual |

0.25 |

240 |

156 |

|

3 |

Collar Sewing |

SNLS |

0.40 |

150 |

98 |

|

4 |

Collar Edge Cut &

Turn |

3T O/L |

0.30 |

200 |

130 |

|

5 |

Collar Top Stitch 1/4 |

SNLS |

0.45 |

133 |

87 |

|

6 |

Collar Band Rolling |

SNLS |

0.30 |

200 |

130 |

|

7 |

Collar Band No. Match |

Manual |

0.25 |

240 |

156 |

|

8 |

Collar Band Attach |

SNLS |

0.50 |

120 |

78 |

|

9 |

Collar Band Top Stitch |

SNLS |

0.40 |

150 |

98 |

|

10 |

Collar Finishing (Edge

Cut) |

3T O/L |

0.35 |

171 |

111 |

|

11 |

Cuff Rolling |

SNLS |

0.30 |

200 |

130 |

|

12 |

Cuff Marking |

Manual |

0.30 |

200 |

130 |

|

13 |

Cuff Sewing |

SNLS |

0.45 |

133 |

87 |

|

14 |

Cuff edge Cut & Turn

|

Manual |

0.40 |

150 |

98 |

|

15 |

Cuff 1/4 Top Stitch |

SNLS |

0.50 |

120 |

78 |

|

Sleeve Make |

|||||

|

16 |

Placket Placement Mark

& Cut |

Manual |

0.30 |

200 |

130 |

|

17 |

Gamble Attach |

SNLS |

0.35 |

171 |

111 |

|

18 |

Gamble Tack & Raw

Edge Cut |

SNLS |

0.30 |

200 |

130 |

|

19 |

Placket Number Match |

Manual |

0.30 |

200 |

130 |

|

20 |

Placket Iron |

Iron |

0.65 |

92 |

60 |

|

21 |

Placket Attach |

SNLS |

0.70 |

86 |

56 |

|

Back Part |

|||||

|

22 |

Dart Tack |

SNLS |

0.30 |

200 |

130 |

|

23 |

Hanger Loop Make &

Attach |

SNLS |

0.35 |

171 |

111 |

|

24 |

Main Label Facing Iron |

Manual |

0.30 |

200 |

130 |

|

25 |

Label Attach at Facing |

SNLS |

0.30 |

200 |

130 |

|

26 |

Facing Attach at Back

Yoke |

SNLS |

0.30 |

200 |

130 |

|

27 |

Back Yoke Number Match |

Manual |

0.30 |

200 |

130 |

|

28 |

Back Yoke Attach |

5T O/L |

0.30 |

200 |

130 |

|

29 |

Back Yoke Top Stitch |

DNCS |

0.30 |

200 |

130 |

|

Front Part |

|||||

|

30 |

Top Center Rolling one side |

MNCS |

0.35 |

171 |

111 |

|

31 |

Top Center Rolling another side |

SNLS |

0.45 |

133 |

87 |

|

32 |

Top Center Iron |

Heat Seal |

0.30 |

200 |

130 |

|

33 |

Front Pocket Placement

Mark |

Manual |

0.40 |

150 |

98 |

|

34 |

Pocket Check Match |

Manual |

0.40 |

150 |

98 |

|

35 |

Pocket Marking |

Manual |

0.35 |

171 |

111 |

|

36 |

Pocket Fitting |

3T O/L |

0.35 |

171 |

111 |

|

37 |

Pocket Rolling |

SNLS |

0.40 |

150 |

98 |

|

38 |

Pocket Iron |

Iron |

0.65 |

92 |

60 |

|

39 |

Front Pocket Attach |

SNLS |

0.65 |

92 |

60 |

|

40 |

Front Pocket 1/4 Top

Stitch |

SNLS |

0.40 |

150 |

98 |

|

41 |

Flap Check &

Number Match |

Manual |

0.35 |

171 |

111 |

|

42 |

Flap Fusing |

Steam Iron |

0.30 |

200 |

130 |

|

43 |

Flap Mark & Sewing |

Pattern Sewer MC |

0.45 |

133 |

87 |

|

44 |

Flap Raw edge Cut

&turn |

3T O/L |

0.40 |

150 |

98 |

|

45 |

Flap Top Stitch |

SNLS |

0.35 |

171 |

111 |

|

46 |

Flap 1/4 Top Stitch |

SNLS |

0.35 |

171 |

111 |

|

47 |

Flap Edge Cut &

Sewing |

DLM |

0.30 |

200 |

130 |

|

48 |

Flap Attach |

SNLS |

0.40 |

150 |

98 |

|

49 |

Flap Top Stitch |

SNLS |

0.30 |

200 |

130 |

|

50 |

Patch Label Attach |

SNLS |

0.30 |

200 |

130 |

|

51 |

Front Fitting |

Manual |

0.30 |

200 |

130 |

|

Assemble |

|||||

|

52 |

Front & Back Number Match |

Manual |

0.30 |

200 |

130 |

|

53 |

Shoulder Join |

SNLS |

0.60 |

100 |

65 |

|

54 |

Shoulder Top Stitch |

DNLS |

0.30 |

200 |

130 |

|

55 |

Collar Mark |

Manual |

0.25 |

240 |

156 |

|

56 |

Collar Number Match

& Mark |

Manual |

0.30 |

200 |

130 |

|

57 |

Collar Attach |

SNLS |

0.50 |

120 |

78 |

|

58 |

Collar Top Stitch.

& Size Label Attach |

SNLS |

0.60 |

100 |

65 |

|

59 |

Sleeve Number Match

& Mark |

Manual |

0.30 |

200 |

130 |

|

60 |

Sleeve Attach |

5T O/L |

0.60 |

100 |

65 |

|

61 |

Arm Hole Top Stitch |

DNCS |

0.60 |

100 |

65 |

|

62 |

Care Label Attach |

SNLS |

0.30 |

200 |

130 |

|

63 |

Side Seam Join |

3T O/L |

0.75 |

80 |

52 |

|

64 |

Side Seam Top Stitch |

FOA |

0.60 |

100 |

65 |

|

65 |

Cuff Number Match

& Mark |

Manual |

0.45 |

133 |

87 |

|

66 |

SNLS |

0.50 |

120 |

78 |

|

|

67 |

Bottom Rolling |

SNLS |

0.60 |

100 |

65 |

|

68 |

All Button Hole |

BH |

0.80 |

75 |

49 |

|

69 |

All Bartack |

B/T |

0.40 |

150 |

98 |

|

70 |

Final Trimming |

Manual |

0.60 |

100 |

65 |

|

|

Total |

|

28.55 |

|

|

Full form of Machine Name:

In the above table short names of sewing machines are written. Followings are the abbreviation of those short machine codes.

- SNLS - Single needle lock stitch

- DNLS - Double needle lock stitch

- DNCS - Double needle chain stitch

- DLM - Single needle lock stitch Edge Cutter

- FOA - Feed of the Arm

- MNCS - Multi needle chain stitch

- 3T O/L - 3 thread over lock

- 5T O/L - 5 thread over lock

- Heat Seal - Heat Seal

- Pattern Sewer MC - Pattern Sewer Machine

- BT - Bartack

- BH - Button Hole

It will be best to set the line layout target based on line efficiency, line cost and delivery date of style.

Formula to set the 100% target:

Daily Target = (Worker x Working hour x 60/ SMV) x efficiency %

Basic Pitch Time (BPT) =Total SMV / Total Manpower

We can use “Ball Point or Sharp Point" needle to stitch this item.

Fabric Types and Needle Size Chart:

Thank you for your patience reading my blog. Please, Share this article with others. It will inspire me to write more about this. Let me know your question about this content.

“Wear a mask to save lives. Clean your hands. Keep at a safe distance.”

No comments

Please let me know if anything needs to be added