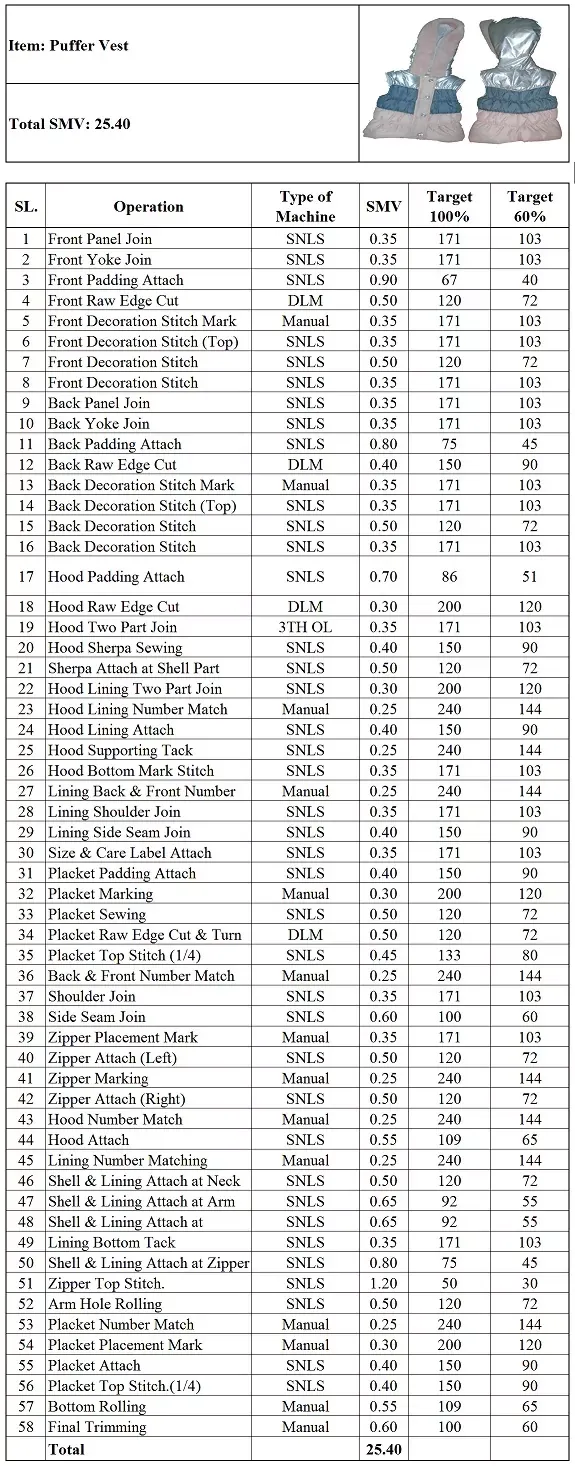

What is the SMV of Puffer Vest?

SMV of Puffer Vest is 25.40. In my industrial engineering tutorial series, I am sharing an Operation Breakdown and SMV of Puffer Vest. You can refer to this operation bulletin to learn about various operations involved, SMV and machine requirements in making Puffer Vest Jacket.

A Puffer Vest is not an easy style to produce in the sewing line. It has lots of complex processes. I have described the operation breakdown of the Puffer Vest with SMV and Machine names here.

Operation Breakdown of Puffer Vest is done by the following table. In this operation bulletin process list, estimated time, machine name, hourly production target quantity at 100% and 60% efficiency are shown. The estimated time (SMV) shown in the below table will vary according to the product method followed and machine and equipment used in actual production. So please be careful while you use the above estimated time against each operation.Operation Breakdown of Puffer Vest

|

SL. |

Operation |

Type

of Machine |

SMV |

Target

100% |

Target

60% |

|

1 |

Front

Panel Join |

SNLS |

0.35 |

171 |

103 |

|

2 |

Front

Yoke Join |

SNLS |

0.35 |

171 |

103 |

|

3 |

Front

Padding Attach |

SNLS |

0.90 |

67 |

40 |

|

4 |

Front

Raw Edge Cut |

DLM |

0.50 |

120 |

72 |

|

5 |

Front

Decoration Stitch Mark |

Manual |

0.35 |

171 |

103 |

|

6 |

Front

Decoration Stitch (Top) |

SNLS |

0.35 |

171 |

103 |

|

7 |

Front

Decoration Stitch (Middle) |

SNLS |

0.50 |

120 |

72 |

|

8 |

Front

Decoration Stitch (Bottom) |

SNLS |

0.35 |

171 |

103 |

|

9 |

Back

Panel Join |

SNLS |

0.35 |

171 |

103 |

|

10 |

Back

Yoke Join |

SNLS |

0.35 |

171 |

103 |

|

11 |

Back

Padding Attach |

SNLS |

0.80 |

75 |

45 |

|

12 |

Back

Raw Edge Cut |

DLM |

0.40 |

150 |

90 |

|

13 |

Back

Decoration Stitch Mark |

Manual |

0.35 |

171 |

103 |

|

14 |

Back

Decoration Stitch (Top) |

SNLS |

0.35 |

171 |

103 |

|

15 |

Back

Decoration Stitch (Middle) |

SNLS |

0.50 |

120 |

72 |

|

16 |

Back

Decoration Stitch (Bottom) |

SNLS |

0.35 |

171 |

103 |

|

17 |

Hood

Padding Attach |

SNLS |

0.70 |

86 |

51 |

|

18 |

Hood

Raw Edge Cut |

DLM |

0.30 |

200 |

120 |

|

19 |

Hood

Two Part Join |

3TH OL |

0.35 |

171 |

103 |

|

20 |

Hood

Sherpa Sewing |

SNLS |

0.40 |

150 |

90 |

|

21 |

Sherpa

Attach at Shell Part |

SNLS |

0.50 |

120 |

72 |

|

22 |

Hood

Lining Two Part Join |

SNLS |

0.30 |

200 |

120 |

|

23 |

Hood

Lining Number Match |

Manual |

0.25 |

240 |

144 |

|

24 |

Hood

Lining Attach |

SNLS |

0.40 |

150 |

90 |

|

25 |

Hood

Supporting Tack |

SNLS |

0.25 |

240 |

144 |

|

26 |

Hood

Bottom Mark Stitch |

SNLS |

0.35 |

171 |

103 |

|

27 |

Lining

Back & Front Number Match |

Manual |

0.25 |

240 |

144 |

|

28 |

Lining

Shoulder Join |

SNLS |

0.35 |

171 |

103 |

|

29 |

Lining

Side Seam Join |

SNLS |

0.40 |

150 |

90 |

|

30 |

Size

& Care Label Attach |

SNLS |

0.35 |

171 |

103 |

|

31 |

Placket

Padding Attach |

SNLS |

0.40 |

150 |

90 |

|

32 |

Placket

Marking |

Manual |

0.30 |

200 |

120 |

|

33 |

Placket

Sewing |

SNLS |

0.50 |

120 |

72 |

|

34 |

Placket

Raw Edge Cut & Turn |

DLM |

0.50 |

120 |

72 |

|

35 |

Placket

Top Stitch (1/4) |

SNLS |

0.45 |

133 |

80 |

|

36 |

Back

& Front Number Match |

Manual |

0.25 |

240 |

144 |

|

37 |

Shoulder

Join |

SNLS |

0.35 |

171 |

103 |

|

38 |

Side

Seam Join |

SNLS |

0.60 |

100 |

60 |

|

39 |

Zipper

Placement Mark |

Manual |

0.35 |

171 |

103 |

|

40 |

Zipper

Attach (Left) |

SNLS |

0.50 |

120 |

72 |

|

41 |

Zipper

Marking |

Manual |

0.25 |

240 |

144 |

|

42 |

Zipper

Attach (Right) |

SNLS |

0.50 |

120 |

72 |

|

43 |

Hood

Number Match |

Manual |

0.25 |

240 |

144 |

|

44 |

Hood

Attach |

SNLS |

0.55 |

109 |

65 |

|

45 |

Lining

Number Matching |

Manual |

0.25 |

240 |

144 |

|

46 |

Shell

& Lining Attach at Neck Side |

SNLS |

0.50 |

120 |

72 |

|

47 |

Shell

& Lining Attach at Arm Hole |

SNLS |

0.65 |

92 |

55 |

|

48 |

Shell

& Lining Attach at Bottom Side |

SNLS |

0.65 |

92 |

55 |

|

49 |

Lining

Bottom Tack |

SNLS |

0.35 |

171 |

103 |

|

50 |

Shell

& Lining Attach at Zipper Side |

SNLS |

0.80 |

75 |

45 |

|

51 |

Zipper

Top Stitch. |

SNLS |

1.20 |

50 |

30 |

|

52 |

Arm

Hole Rolling |

SNLS |

0.50 |

120 |

72 |

|

53 |

Placket

Number Match |

Manual |

0.25 |

240 |

144 |

|

54 |

Placket

Placement Mark |

Manual |

0.30 |

200 |

120 |

|

55 |

Placket

Attach |

SNLS |

0.40 |

150 |

90 |

|

56 |

Placket

Top Stitch.(1/4) |

SNLS |

0.40 |

150 |

90 |

|

57 |

Bottom

Rolling |

Manual |

0.55 |

109 |

65 |

|

58 |

Final

Trimming |

Manual |

0.60 |

100 |

60 |

|

|

Total |

|

25.40 |

|

|

Full form of Machine Name:

In the above table a short name of sewing machines is written. Followings are the abbreviation of those short machine codes.

SNLS - Single needle lock stitch

SNCS - Double needle lock stitch

3T O/L - 3 Thread over lock

DLM - Single needle edge side cutter

Manual - Helper

We can use “Ball Point needle or Sharp Point" Needle to stitch this item:

Single Needle Lock-stitch --- DB 1

Single Needle Edge Side Cutter --- DB 1

Three / Five Thread Overlock --- DC 21

|

Fabric Types |

Needle Size |

|

Very fine fabrics (silk, chiffon, organza, voile, lace) |

8, 9, 10 |

|

Light weight fabrics (cotton, heavier silks, synthetics, spandex, lycra) |

11, 12 |

|

Medium weight fabrics (velvet, fine corduroy, linen, muslin, tricot, knits, fleece) |

14 |

|

Heavy weight fabrics (denim, leather, canvas, suiting) |

16 |

|

Very heavy weight fabrics (heavy denim, upholstery fabric, faux fur) |

18, 19 |

|

Extra heavy fabrics |

20, 21 |

- Operation Breakdown of Ladies Fake Down Vest Jacket

- Operation Breakdown of Boys Rain Jacket

- Operation Breakdown of Loose Padding Jacket

- Operation Breakdown of Hoodie Vest

- Operation breakdown of Hoodie Jacket (Puffer)

- Operation Bulletin of Vest

- Operation Bulletin of Flannel Jacket (Padded)

- Operation Breakdown and SMV of Jacket (Padded Softshell)

- Operation Bulletin of Denim Jacket (Men)

- What is operation breakdown in the garment industry?

Operation Bulletin makes our work easy to set up a production line in the apparel industry. We can easily manage machine and operator requirements for any sewing line by this. But it is necessary to do an operation breakdown to prepare a machine layout and line balancing by industrial engineering (IE).

Find out more about what is operation breakdown. You can visit my website to learn more about the bulletin or breakdown of garments.

Thank you for your patience reading. Please, Share this article with others. It will inspire me to write more about this. Please subscribe to my page.

“Wear a mask to save lives. Clean your hands. Keep at a safe distance.”

No comments

Please let me know if anything needs to be added