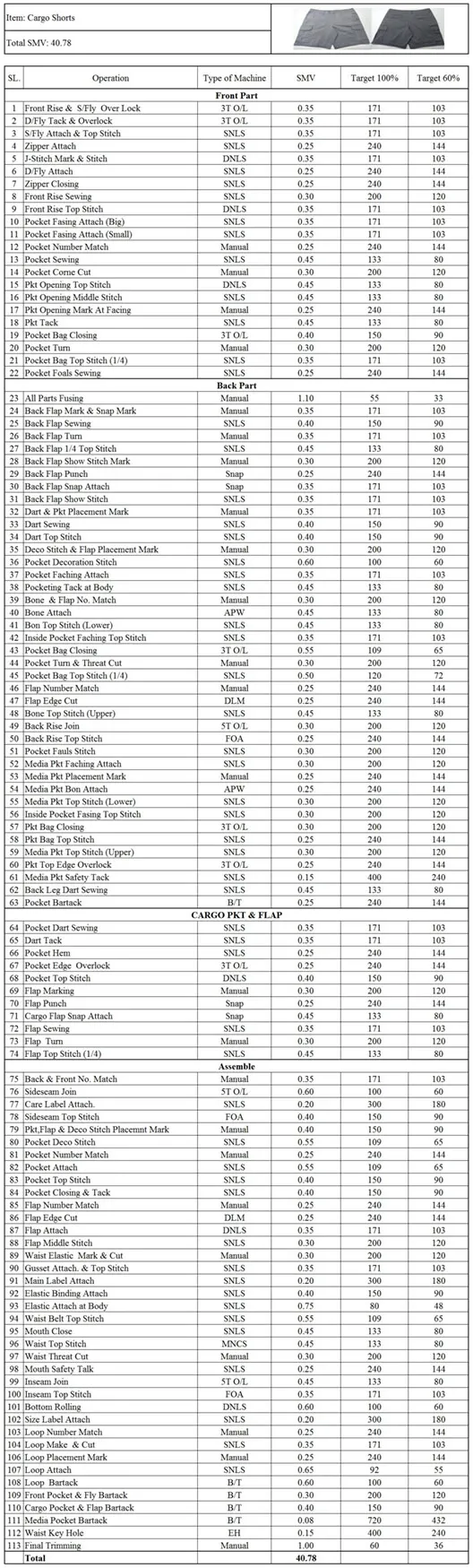

Operation Bulletin of a Cargo Shorts

In my Industrial Engineering (IE) tutorial series, I am sharing an operation bulletin of a Cargo Shorts. You can refer to this operation bulletin to learn about various operations involved and machine requirements in making Cargo Shorts. But in this post, I describe the operation bulletin of a Cargo Shorts.

Operation Bulletin of a Cargo Shorts is done by the following table. In this Operation Bulletin, Operation list, estimated time, Machine name, Hourly production target quantity at 100% and 60% efficiency are shown. The estimated time (SMV) shown in the below table will vary according to the product method followed and machine and equipment used in actual production. So please be careful while you use the above estimated time against each operation.

Operation Bulletin of a Cargo Shorts

|

SL. |

Operation |

Type of Machine |

SMV |

Target 100% |

Target 60% |

|

Front Part |

|||||

|

1 |

Front Rise & S/Fly

Over Lock |

3T O/L |

0.35 |

171 |

103 |

|

2 |

D/Fly Tack & Overlock |

3T O/L |

0.35 |

171 |

103 |

|

3 |

S/Fly Attach & Top Stitch |

SNLS |

0.35 |

171 |

103 |

|

4 |

Zipper Attach |

SNLS |

0.25 |

240 |

144 |

|

5 |

J-Stitch Mark & Stitch |

DNLS |

0.35 |

171 |

103 |

|

6 |

D/Fly Attach |

SNLS |

0.25 |

240 |

144 |

|

7 |

Zipper Closing |

SNLS |

0.25 |

240 |

144 |

|

8 |

Front Rise Sewing |

SNLS |

0.30 |

200 |

120 |

|

9 |

Front Rise Top Stitch |

DNLS |

0.35 |

171 |

103 |

|

10 |

Pocket Facing Attach (Big) |

SNLS |

0.35 |

171 |

103 |

|

11 |

Pocket Facing Attach (Small) |

SNLS |

0.35 |

171 |

103 |

|

12 |

Pocket Number Match |

Manual |

0.25 |

240 |

144 |

|

13 |

Pocket Sewing |

SNLS |

0.45 |

133 |

80 |

|

14 |

Pocket Corner Cut |

Manual |

0.30 |

200 |

120 |

|

15 |

Pocket Opening Top Stitch |

DNLS |

0.45 |

133 |

80 |

|

16 |

Pocket Opening Middle Stitch |

SNLS |

0.45 |

133 |

80 |

|

17 |

Pocket Opening Mark At Facing |

Manual |

0.25 |

240 |

144 |

|

18 |

Pocket Tack |

SNLS |

0.45 |

133 |

80 |

|

19 |

Pocket Bag Closing |

3T O/L |

0.40 |

150 |

90 |

|

20 |

Pocket Turn |

Manual |

0.30 |

200 |

120 |

|

21 |

Pocket Bag Top Stitch (1/4) |

SNLS |

0.35 |

171 |

103 |

|

22 |

Pocket Foals Sewing |

SNLS |

0.25 |

240 |

144 |

|

Back Part |

|||||

|

23 |

All Parts Fusing |

Manual |

1.10 |

55 |

33 |

|

24 |

Back Flap Mark & Snap Mark |

Manual |

0.35 |

171 |

103 |

|

25 |

Back Flap Sewing |

SNLS |

0.40 |

150 |

90 |

|

26 |

Back Flap Turn |

Manual |

0.35 |

171 |

103 |

|

27 |

Back Flap 1/4 Top Stitch |

SNLS |

0.45 |

133 |

80 |

|

28 |

Back Flap Show Stitch Mark |

Manual |

0.30 |

200 |

120 |

|

29 |

Back Flap Punch |

Snap |

0.25 |

240 |

144 |

|

30 |

Back Flap Snap Attach |

Snap |

0.35 |

171 |

103 |

|

31 |

Back Flap Show Stitch |

SNLS |

0.35 |

171 |

103 |

|

32 |

Dart & Pocket Placement Mark |

Manual |

0.35 |

171 |

103 |

|

33 |

Dart Sewing |

SNLS |

0.40 |

150 |

90 |

|

34 |

Dart Top Stitch |

SNLS |

0.40 |

150 |

90 |

|

35 |

Deco Stitch & Flap Placement

Mark |

Manual |

0.30 |

200 |

120 |

|

36 |

Pocket Decoration Stitch |

SNLS |

0.60 |

100 |

60 |

|

37 |

Pocket Facing Attach |

SNLS |

0.35 |

171 |

103 |

|

38 |

Pocketing Tack at Body |

SNLS |

0.45 |

133 |

80 |

|

39 |

Bone & Flap No. Match |

Manual |

0.30 |

200 |

120 |

|

40 |

Bone Attach |

APW |

0.45 |

133 |

80 |

|

41 |

Bon Top Stitch (Lower) |

SNLS |

0.45 |

133 |

80 |

|

42 |

Inside Pocket Facing Top Stitch |

SNLS |

0.35 |

171 |

103 |

|

43 |

Pocket Bag Closing |

3T O/L |

0.55 |

109 |

65 |

|

44 |

Pocket Turn & Threat Cut |

Manual |

0.30 |

200 |

120 |

|

45 |

Pocket Bag Top Stitch (1/4) |

SNLS |

0.50 |

120 |

72 |

|

46 |

Flap Number Match |

Manual |

0.25 |

240 |

144 |

|

47 |

Flap Edge Cut |

DLM |

0.25 |

240 |

144 |

|

48 |

Bone Top Stitch (Upper) |

SNLS |

0.45 |

133 |

80 |

|

49 |

Back Rise Join |

5T O/L |

0.30 |

200 |

120 |

|

50 |

Back Rise Top Stitch |

FOA |

0.25 |

240 |

144 |

|

51 |

Pocket Fauls Stitch |

SNLS |

0.30 |

200 |

120 |

|

52 |

Media Pocket Facing Attach |

SNLS |

0.30 |

200 |

120 |

|

53 |

Media Pocket Placement Mark |

Manual |

0.25 |

240 |

144 |

|

54 |

Media Pocket Bon Attach |

APW |

0.25 |

240 |

144 |

|

55 |

Media Pocket Top Stitch (Lower) |

SNLS |

0.30 |

200 |

120 |

|

56 |

Inside Pocket Facing Top Stitch |

SNLS |

0.30 |

200 |

120 |

|

57 |

Pocket Bag Closing |

3T O/L |

0.30 |

200 |

120 |

|

58 |

Pocket Bag Top Stitch |

SNLS |

0.25 |

240 |

144 |

|

59 |

Media Pocket Top Stitch (Upper) |

SNLS |

0.30 |

200 |

120 |

|

60 |

Pocket Top Edge Overlock |

3T O/L |

0.25 |

240 |

144 |

|

61 |

Media Pocket Safety Tack |

SNLS |

0.15 |

400 |

240 |

|

62 |

Back Leg Dart Sewing |

SNLS |

0.45 |

133 |

80 |

|

63 |

Pocket Bartack |

B/T |

0.25 |

240 |

144 |

|

CARGO POCKET & FLAP |

|||||

|

64 |

Pocket Dart Sewing |

SNLS |

0.35 |

171 |

103 |

|

65 |

Dart Tack |

SNLS |

0.35 |

171 |

103 |

|

66 |

Pocket Hem |

SNLS |

0.25 |

240 |

144 |

|

67 |

Pocket Edge Overlock |

3T O/L |

0.25 |

240 |

144 |

|

68 |

Pocket Top Stitch |

DNLS |

0.40 |

150 |

90 |

|

69 |

Flap Marking |

Manual |

0.30 |

200 |

120 |

|

70 |

Flap Punch |

Snap |

0.25 |

240 |

144 |

|

71 |

Cargo Flap Snap Attach |

Snap |

0.45 |

133 |

80 |

|

72 |

Flap Sewing |

SNLS |

0.35 |

171 |

103 |

|

73 |

Flap Turn |

Manual |

0.30 |

200 |

120 |

|

74 |

Flap Top Stitch (1/4) |

SNLS |

0.45 |

133 |

80 |

|

Assemble |

|||||

|

75 |

Back & Front No. Match |

Manual |

0.35 |

171 |

103 |

|

76 |

Side seam Join |

5T O/L |

0.60 |

100 |

60 |

|

77 |

Care Label Attach. |

SNLS |

0.20 |

300 |

180 |

|

78 |

Side seam Top Stitch |

FOA |

0.40 |

150 |

90 |

|

79 |

Pocket,

Flap & Deco Stitch Placement Mark |

Manual |

0.40 |

150 |

90 |

|

80 |

Pocket Deco Stitch |

SNLS |

0.55 |

109 |

65 |

|

81 |

Pocket Number Match |

Manual |

0.25 |

240 |

144 |

|

82 |

Pocket Attach |

SNLS |

0.55 |

109 |

65 |

|

83 |

Pocket Top Stitch |

SNLS |

0.40 |

150 |

90 |

|

84 |

Pocket Closing & Tack |

SNLS |

0.40 |

150 |

90 |

|

85 |

Flap Number Match |

Manual |

0.25 |

240 |

144 |

|

86 |

Flap Edge Cut |

DLM |

0.25 |

240 |

144 |

|

87 |

Flap Attach |

DNLS |

0.35 |

171 |

103 |

|

88 |

Flap Middle Stitch |

SNLS |

0.30 |

200 |

120 |

|

89 |

Waist Elastic Mark & Cut |

Manual |

0.30 |

200 |

120 |

|

90 |

Gusset Attach. & Top Stitch |

SNLS |

0.35 |

171 |

103 |

|

91 |

Main Label Attach |

SNLS |

0.20 |

300 |

180 |

|

92 |

Elastic Binding Attach |

SNLS |

0.40 |

150 |

90 |

|

93 |

Elastic Attach at Body |

SNLS |

0.75 |

80 |

48 |

|

94 |

Waist Belt Top Stitch |

SNLS |

0.55 |

109 |

65 |

|

95 |

Mouth Close |

SNLS |

0.45 |

133 |

80 |

|

96 |

Waist Top Stitch |

MNCS |

0.45 |

133 |

80 |

|

97 |

Waist Threat Cut |

Manual |

0.30 |

200 |

120 |

|

98 |

Mouth Safety Talk |

SNLS |

0.25 |

240 |

144 |

|

99 |

Inseam Join |

5T O/L |

0.45 |

133 |

80 |

|

100 |

Inseam Top Stitch |

FOA |

0.35 |

171 |

103 |

|

101 |

Bottom Rolling |

DNLS |

0.60 |

100 |

60 |

|

102 |

Size Label Attach |

SNLS |

0.20 |

300 |

180 |

|

103 |

Loop Number Match |

Manual |

0.25 |

240 |

144 |

|

104 |

Loop Make & Cut |

SNLS |

0.35 |

171 |

103 |

|

106 |

Loop Placement Mark |

Manual |

0.25 |

240 |

144 |

|

107 |

Loop Attach |

SNLS |

0.65 |

92 |

55 |

|

108 |

Loop Bartack |

B/T |

0.60 |

100 |

60 |

|

109 |

Front Pocket & Fly Bartack |

B/T |

0.30 |

200 |

120 |

|

110 |

Cargo Pocket & Flap Bartack |

B/T |

0.40 |

150 |

90 |

|

111 |

Media Pocket Bartack |

B/T |

0.08 |

720 |

432 |

|

112 |

Waist Key Hole |

EH |

0.15 |

400 |

240 |

|

113 |

Final Trimming |

Manual |

1.00 |

60 |

36 |

|

|

Total |

|

40.78 |

|

|

Full form of Machine Name:

- SNLS - Single needle lock stitch

- DNLS - Double needle lock stitch

- APW Machine - Auto Welt Pocket Machine

- 3T O/L - 3 Thread over lock

- 5T O/L - 5 Thread over lock

- DLM - Single needle lock stitch Edge Cutter

- FOA - Feed of the Arm

- MNCS - Multi needle chain stitch

- EH - Eyelet Hole

- SNAP - Snap Button Machine

- B/T - Bartack

- Manual - Helper

Set the line target:

It will be best to set the line layout target based on line efficiency, line cost and delivery date of style.

Daily Target = (Worker x Working hour x 60/ SMV) x efficiency %

Basic Pitch Time (BPT) =Total SMV / Total Manpower

We can use “Ball Point or Sharp Point" needle to stitch this item.

Fabric Types and Needle Size Chart:

|

Fabric Types |

Needle Size |

|

Very fine fabrics (silk, chiffon,

organza, voile, lace) |

8, 9, 10 |

|

Light weight fabrics (cotton,

heavier silks, synthetics, spandex, lycra) |

11, 12 |

|

Medium weight fabrics (velvet,

fine corduroy, linen, muslin, tricot, knits, fleece) |

14 |

|

Heavy weight fabrics (denim,

leather, canvas, suiting) |

16 |

|

Very heavy weight fabrics (heavy

denim, upholstery fabric, faux fur) |

18, 19 |

|

Extra heavy fabrics |

20, 21 |

Operation Bulletin makes our work easy to set up a production line. We easily manage machine and operator requirements for any sewing line by this. But it is necessary to do an Operation Bulletin of Cargo Shorts to prepare a machine layout and line balancing by industrial engineering (IE).

I have create some process video which can help sewing lovers, IE, Garments/Apparel manufacturer. Please follow and watch the Waistband top stitch video

It is helpful to me. Thanks

ReplyDeleteappriciate your sharing

ReplyDelete