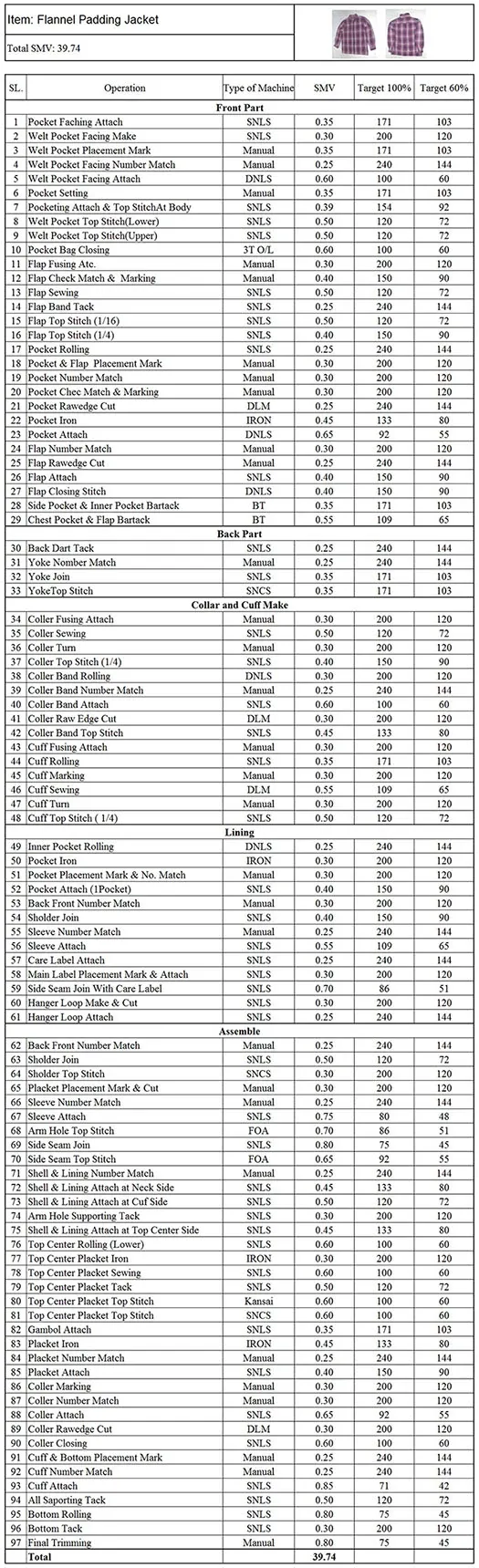

Operation Bulletin of Flannel Jacket (Padded)

In my industrial engineering tutorial series, I am sharing an operation bulletin of Flannel Jacket (Padded). You can refer to this operation bulletin to learn about various operations involved, SMV and machine requirements in making Flannel Jacket (Padded).

A flannel Jacket (Padded) is not an easy style to produce in the sewing line. It has lots of complex processes. Here I describe the operation breakdown of the Flannel Jacket (Padded) with SMV and Machine name.

Operation Bulletin of Flannel Jacket (Padded) is done by the following table. In this operation bulletin process list, estimated time, machine name, hourly production target quantity at 100% and 60% efficiency are shown. The estimated time (SMV) shown in the below table will vary according to the product method followed and machine and equipment used in actual production. So please be careful while you use the above estimated time against each operation.Operation Bulletin of Flannel Jacket (Padded)

|

SL. |

Operation |

Type of Machine |

SMV |

Target 100% |

Target 60% |

|

Front Part |

|||||

|

1 |

Pocket Facing Attach |

SNLS |

0.35 |

171 |

103 |

|

2 |

Welt Pocket Facing Make |

SNLS |

0.30 |

200 |

120 |

|

3 |

Welt Pocket Placement Mark |

Manual |

0.35 |

171 |

103 |

|

4 |

Welt Pocket Facing Number

Match |

Manual |

0.25 |

240 |

144 |

|

5 |

Welt Pocket Facing Attach |

DNLS |

0.60 |

100 |

60 |

|

6 |

Pocket Setting |

Manual |

0.35 |

171 |

103 |

|

7 |

Pocketing Attach & Top

Stitch at Body |

SNLS |

0.39 |

154 |

92 |

|

8 |

Welt Pocket Top

Stitch(Lower) |

SNLS |

0.50 |

120 |

72 |

|

9 |

Welt Pocket Top

Stitch(Upper) |

SNLS |

0.50 |

120 |

72 |

|

10 |

Pocket Bag Closing |

3T O/L |

0.60 |

100 |

60 |

|

11 |

Flap Fusing Attach. |

Manual |

0.30 |

200 |

120 |

|

12 |

Flap Check Match & Marking |

Manual |

0.40 |

150 |

90 |

|

13 |

Flap Sewing |

SNLS |

0.50 |

120 |

72 |

|

14 |

Flap Band Tack |

SNLS |

0.25 |

240 |

144 |

|

15 |

Flap Top Stitch (1/16) |

SNLS |

0.50 |

120 |

72 |

|

16 |

Flap Top Stitch (1/4) |

SNLS |

0.40 |

150 |

90 |

|

17 |

Pocket Rolling |

SNLS |

0.25 |

240 |

144 |

|

18 |

Pocket & Flap Placement Mark |

Manual |

0.30 |

200 |

120 |

|

19 |

Pocket Number Match |

Manual |

0.30 |

200 |

120 |

|

20 |

Pocket Check Match &

Marking |

Manual |

0.30 |

200 |

120 |

|

21 |

Pocket Raw Edge Cut |

DLM |

0.25 |

240 |

144 |

|

22 |

Pocket Iron |

IRON |

0.45 |

133 |

80 |

|

23 |

Pocket Attach |

DNLS |

0.65 |

92 |

55 |

|

24 |

Flap Number Match |

Manual |

0.30 |

200 |

120 |

|

25 |

Flap Raw Edge Cut |

Manual |

0.25 |

240 |

144 |

|

26 |

Flap Attach |

SNLS |

0.40 |

150 |

90 |

|

27 |

Flap Closing Stitch |

DNLS |

0.40 |

150 |

90 |

|

28 |

Side Pocket & Inner

Pocket Bartack |

BT |

0.35 |

171 |

103 |

|

29 |

Chest Pocket & Flap

Bartack |

BT |

0.55 |

109 |

65 |

|

Back Part |

|||||

|

30 |

Back Dart Tack |

SNLS |

0.25 |

240 |

144 |

|

31 |

Yoke Number Match |

Manual |

0.25 |

240 |

144 |

|

32 |

Yoke Join |

SNLS |

0.35 |

171 |

103 |

|

Collar and Cuff Make |

|||||

|

34 |

Collar Fusing Attach |

Manual |

0.30 |

200 |

120 |

|

35 |

Collar Sewing |

SNLS |

0.50 |

120 |

72 |

|

36 |

Collar Turn |

Manual |

0.30 |

200 |

120 |

|

37 |

Collar Top Stitch (1/4) |

SNLS |

0.40 |

150 |

90 |

|

38 |

Collar Band Rolling |

DNLS |

0.30 |

200 |

120 |

|

39 |

Collar Band Number Match |

Manual |

0.25 |

240 |

144 |

|

40 |

Collar Band Attach |

SNLS |

0.60 |

100 |

60 |

|

41 |

Collar Raw Edge Cut |

DLM |

0.30 |

200 |

120 |

|

42 |

Collar Band Top Stitch |

SNLS |

0.45 |

133 |

80 |

|

43 |

Cuff Fusing Attach |

Manual |

0.30 |

200 |

120 |

|

44 |

Cuff Rolling |

SNLS |

0.35 |

171 |

103 |

|

45 |

Cuff Marking |

Manual |

0.30 |

200 |

120 |

|

46 |

Cuff Sewing |

DLM |

0.55 |

109 |

65 |

|

47 |

Cuff Turn |

Manual |

0.30 |

200 |

120 |

|

48 |

Cuff Top Stitch ( 1/4) |

SNLS |

0.50 |

120 |

72 |

|

Lining |

|||||

|

49 |

Inner Pocket Rolling |

DNLS |

0.25 |

240 |

144 |

|

50 |

Pocket Iron |

IRON |

0.30 |

200 |

120 |

|

51 |

Pocket Placement Mark &

No. Match |

Manual |

0.30 |

200 |

120 |

|

52 |

Pocket Attach (1Pocket) |

SNLS |

0.40 |

150 |

90 |

|

53 |

Back Front Number Match |

Manual |

0.30 |

200 |

120 |

|

54 |

Shoulder Join |

SNLS |

0.40 |

150 |

90 |

|

55 |

Sleeve Number Match |

Manual |

0.25 |

240 |

144 |

|

56 |

Sleeve Attach |

SNLS |

0.55 |

109 |

65 |

|

57 |

Care Label Attach |

SNLS |

0.25 |

240 |

144 |

|

58 |

Main Label Placement Mark

& Attach |

SNLS |

0.30 |

200 |

120 |

|

59 |

Side Seam Join With Care

Label |

SNLS |

0.70 |

86 |

51 |

|

60 |

Hanger Loop Make & Cut |

SNLS |

0.30 |

200 |

120 |

|

61 |

Hanger Loop Attach |

SNLS |

0.25 |

240 |

144 |

|

Assemble |

|||||

|

62 |

Back Front Number Match |

Manual |

0.25 |

240 |

144 |

|

63 |

Shoulder Join |

SNLS |

0.50 |

120 |

72 |

|

64 |

Shoulder Top Stitch |

SNCS |

0.30 |

200 |

120 |

|

65 |

Placket Placement Mark

& Cut |

Manual |

0.30 |

200 |

120 |

|

66 |

Sleeve Number Match |

Manual |

0.25 |

240 |

144 |

|

67 |

Sleeve Attach |

SNLS |

0.75 |

80 |

48 |

|

68 |

Arm Hole Top Stitch |

FOA |

0.70 |

86 |

51 |

|

69 |

Side Seam Join |

SNLS |

0.80 |

75 |

45 |

|

70 |

Side Seam Top Stitch |

FOA |

0.65 |

92 |

55 |

|

71 |

Shell & Lining Number

Match |

Manual |

0.25 |

240 |

144 |

|

72 |

Shell & Lining Attach

at Neck Side |

SNLS |

0.45 |

133 |

80 |

|

73 |

Shell & Lining Attach

at Cuff Side |

SNLS |

0.50 |

120 |

72 |

|

74 |

Arm Hole Supporting Tack |

SNLS |

0.30 |

200 |

120 |

|

75 |

Shell & Lining Attach

at Top Center Side |

SNLS |

0.45 |

133 |

80 |

|

76 |

Top Center Rolling (Lower) |

SNLS |

0.60 |

100 |

60 |

|

77 |

Top Center Placket Iron |

IRON |

0.30 |

200 |

120 |

|

78 |

Top Center Placket Sewing |

SNLS |

0.60 |

100 |

60 |

|

79 |

Top Center Placket Tack |

SNLS |

0.50 |

120 |

72 |

|

80 |

Top Center Placket Top

Stitch |

Kansai |

0.60 |

100 |

60 |

|

81 |

Top Center Placket Top

Stitch |

SNCS |

0.60 |

100 |

60 |

|

82 |

Gambol Attach |

SNLS |

0.35 |

171 |

103 |

|

83 |

Placket Iron |

IRON |

0.45 |

133 |

80 |

|

84 |

Placket Number Match |

Manual |

0.25 |

240 |

144 |

|

85 |

Placket Attach |

SNLS |

0.40 |

150 |

90 |

|

86 |

Collar Marking |

Manual |

0.30 |

200 |

120 |

|

87 |

Collar Number Match |

Manual |

0.30 |

200 |

120 |

|

88 |

Collar Attach |

SNLS |

0.65 |

92 |

55 |

|

89 |

Collar Raw Edge Cut |

DLM |

0.30 |

200 |

120 |

|

90 |

Collar Closing |

SNLS |

0.60 |

100 |

60 |

|

91 |

Cuff & Bottom Placement

Mark |

Manual |

0.25 |

240 |

144 |

|

92 |

Cuff Number Match |

Manual |

0.25 |

240 |

144 |

|

93 |

Cuff Attach |

SNLS |

0.85 |

71 |

42 |

|

94 |

All Supporting Tack |

SNLS |

0.50 |

120 |

72 |

|

95 |

Bottom Rolling |

SNLS |

0.80 |

75 |

45 |

|

96 |

Bottom Tack |

SNLS |

0.30 |

200 |

120 |

|

97 |

Final Trimming |

Manual |

0.80 |

75 |

45 |

|

|

Total |

|

39.74 |

|

|

Full form of Machine Name:

In the above table a short name of sewing machines is written. Followings are the abbreviation of those short machine codes.

- SNLS - Single needle lock stitch

- SNCS - Double needle Chain stitch

- DNLS - Double needle lock stitch

- DNCS - Double needle Chain stitch

- FOA - Feed of the Arm

- 3T O/L - 3 Thread over lock

- BT - Bartack

- Manual - Helper

To set the line layout target:

It will be best to set the line layout target based on line efficiency, line cost and delivery date of style.

Formula to set the 100% target:

Daily Target = (Worker x Working hour x 60/ SMV) x efficiency %

Basic Pitch Time (BPT) =Total SMV / Total Manpower

We can use “Ball Point or Sharp Point" Needle to stitch this item.

Fabric Types and Needle Size Chart:

|

Fabric Types |

Needle Size |

|

Very fine fabrics (silk, chiffon,

organza, voile, lace) |

8, 9, 10 |

|

Light weight fabrics (cotton,

heavier silks, synthetics, spandex, lycra) |

11, 12 |

|

Medium weight fabrics (velvet,

fine corduroy, linen, muslin, tricot, knits, fleece) |

14 |

|

Heavy weight fabrics (denim,

leather, canvas, suiting) |

16 |

- Operation Breakdown of Ladies Fake Down Vest Jacket

- Operation Breakdown of Boys Rain Jacket

- Operation Breakdown of Loose Padding Jacket

- What is the SMV of Puffer Vest?

- Operation Breakdown of Hoodie Vest

- Operation breakdown of Hoodie Jacket (Puffer)

- Operation Bulletin of Vest

- Operation Breakdown and SMV of Jacket (Padded Softshell)

- Operation Bulletin of Denim Jacket (Men)

- What is operation breakdown in the garment industry?

Operation Bulletin makes our work easy to set up a production line in the apparel industry. We can easily manage machine and operator requirements for any sewing line by this. But it is necessary to do an operation breakdown to prepare a machine layout and line balancing by industrial engineering (IE).

Do you want to learn more about "what is operation breakdown?" You can visit my post to learn more about bulletin or breakdown of garments. in the garment industry.

Thank you for your patience reading my blog post. Please, Share this article with others. It will inspire me to write more about this. Please keep in touch with my page to know the update. Let me know your questions about this content.

“Wear a mask to save lives. Clean your hands. Keep at a safe distance.”

It is very helpful post

ReplyDelete