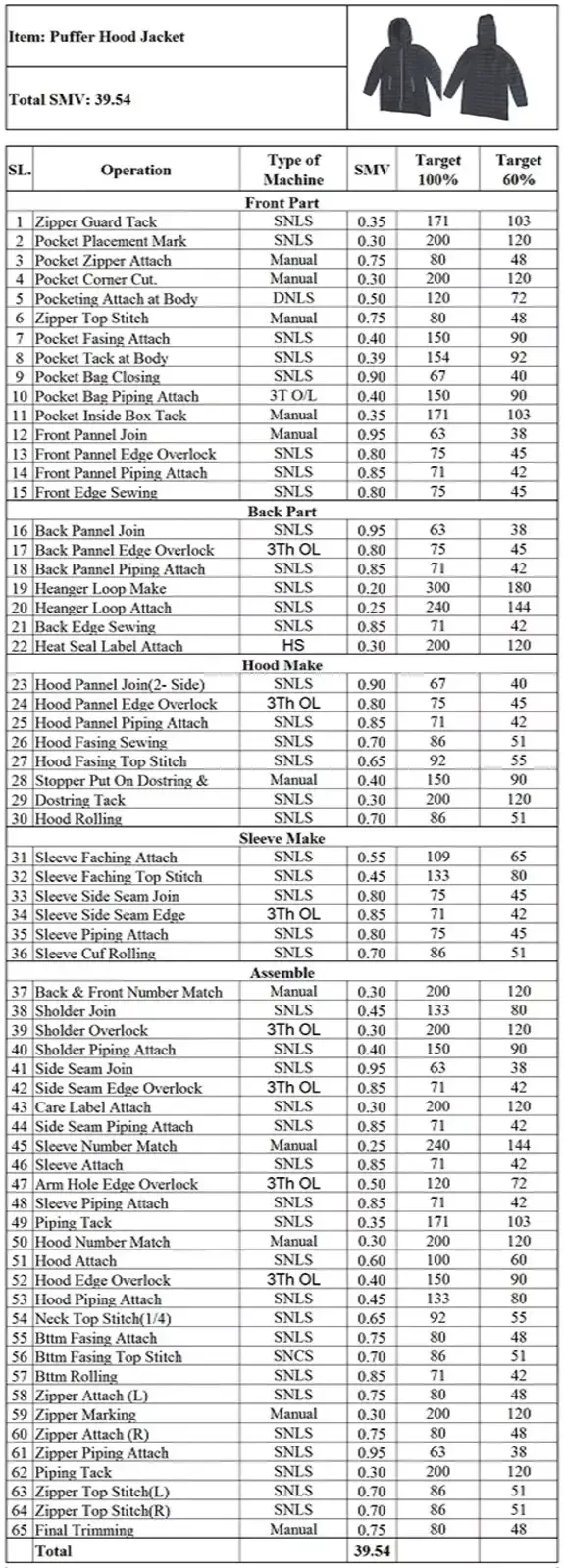

Operation breakdown of Hoodie Jacket (Puffer)

A Puffer Hoodie Jacket is not an easy style to produce in the sewing line. It has lots of complex processes. It has Two welt Pockets. Here I describe the operation breakdown of Puffer Hoodie Jacket with SMV and Machine name.

Operation breakdown of Hoodie Jacket (Puffer)

|

SL. |

Operation |

Type

of Machine |

SMV |

Target

100% |

Target

60% |

|

Front

Part |

|||||

|

1 |

Zipper Guard Tack |

SNLS |

0.35 |

171 |

103 |

|

2 |

Pocket Placement Mark |

SNLS |

0.30 |

200 |

120 |

|

3 |

Pocket Zipper Attach |

Manual |

0.75 |

80 |

48 |

|

4 |

Pocket Corner Cut. |

Manual |

0.30 |

200 |

120 |

|

5 |

Pocketing Attach at Body |

DNLS |

0.50 |

120 |

72 |

|

6 |

Zipper Top Stitch |

Manual |

0.75 |

80 |

48 |

|

7 |

Pocket Facing Attach |

SNLS |

0.40 |

150 |

90 |

|

8 |

Pocket Tack at Body |

SNLS |

0.39 |

154 |

92 |

|

9 |

Pocket Bag Closing |

SNLS |

0.90 |

67 |

40 |

|

10 |

Pocket Bag Piping Attach |

3T O/L |

0.40 |

150 |

90 |

|

11 |

Pocket Inside Box Tack |

Manual |

0.35 |

171 |

103 |

|

12 |

Front Panel Join |

Manual |

0.95 |

63 |

38 |

|

13 |

Front Panel Edge Overlock |

SNLS |

0.80 |

75 |

45 |

|

14 |

Front Panel Piping Attach |

SNLS |

0.85 |

71 |

42 |

|

15 |

Front Edge Sewing |

SNLS |

0.80 |

75 |

45 |

|

Back Part |

|||||

|

16 |

Back Panel Join |

SNLS |

0.95 |

63 |

38 |

|

17 |

Back Panel Edge Overlock |

3Th OL |

0.80 |

75 |

45 |

|

18 |

Back Panel Piping Attach |

SNLS |

0.85 |

71 |

42 |

|

19 |

Hanger Loop Make |

SNLS |

0.20 |

300 |

180 |

|

20 |

Hanger Loop Attach |

SNLS |

0.25 |

240 |

144 |

|

21 |

Back Edge Sewing |

SNLS |

0.85 |

71 |

42 |

|

22 |

Heat Seal Label Attach |

HS |

0.30 |

200 |

120 |

|

Hood Make |

|||||

|

23 |

Hood Panel Join(2- Side) |

SNLS |

0.90 |

67 |

40 |

|

24 |

Hood Panel Edge Overlock |

3Th OL |

0.80 |

75 |

45 |

|

25 |

Hood Panel Piping Attach |

SNLS |

0.85 |

71 |

42 |

|

26 |

Hood Facing Sewing |

SNLS |

0.70 |

86 |

51 |

|

27 |

Hood Facing Top Stitch |

SNLS |

0.65 |

92 |

55 |

|

28 |

Stopper Put On Drawstring & Drawstring Cut. |

Manual |

0.40 |

150 |

90 |

|

29 |

Drawstring Tack |

SNLS |

0.30 |

200 |

120 |

|

30 |

Hood Rolling |

SNLS |

0.70 |

86 |

51 |

|

Sleeve Make |

|||||

|

31 |

Sleeve Facing Attach |

SNLS |

0.55 |

109 |

65 |

|

32 |

Sleeve Facing Top Stitch |

SNLS |

0.45 |

133 |

80 |

|

33 |

Sleeve Side Seam Join |

SNLS |

0.80 |

75 |

45 |

|

34 |

Sleeve Side Seam Edge Overlock |

3Th OL |

0.85 |

71 |

42 |

|

35 |

Sleeve Piping Attach |

SNLS |

0.80 |

75 |

45 |

|

36 |

Sleeve Cuff Rolling |

SNLS |

0.70 |

86 |

51 |

|

Assemble |

|||||

|

37 |

Back & Front Number Match |

Manual |

0.30 |

200 |

120 |

|

38 |

Shoulder Join |

SNLS |

0.45 |

133 |

80 |

|

39 |

Shoulder Overlock |

3Th OL |

0.30 |

200 |

120 |

|

40 |

Shoulder Piping Attach |

SNLS |

0.40 |

150 |

90 |

|

41 |

Side Seam Join |

SNLS |

0.95 |

63 |

38 |

|

42 |

Side Seam Edge Overlock |

3Th OL |

0.85 |

71 |

42 |

|

43 |

Care Label Attach |

SNLS |

0.30 |

200 |

120 |

|

44 |

Side Seam Piping Attach |

SNLS |

0.85 |

71 |

42 |

|

45 |

Sleeve Number Match |

Manual |

0.25 |

240 |

144 |

|

46 |

Sleeve Attach |

SNLS |

0.85 |

71 |

42 |

|

47 |

Arm Hole Edge Overlock |

3Th OL |

0.50 |

120 |

72 |

|

48 |

Sleeve Piping Attach |

SNLS |

0.85 |

71 |

42 |

|

49 |

Piping Tack |

SNLS |

0.35 |

171 |

103 |

|

50 |

Hood Number Match |

Manual |

0.30 |

200 |

120 |

|

51 |

Hood Attach |

SNLS |

0.60 |

100 |

60 |

|

52 |

Hood Edge Overlock |

3Th OL |

0.40 |

150 |

90 |

|

53 |

Hood Piping Attach |

SNLS |

0.45 |

133 |

80 |

|

54 |

Neck Top Stitch(1/4) |

SNLS |

0.65 |

92 |

55 |

|

55 |

Bottom Facing Attach |

SNLS |

0.75 |

80 |

48 |

|

56 |

Bottom Facing Top Stitch |

SNCS |

0.70 |

86 |

51 |

|

57 |

Bottom Rolling |

SNLS |

0.85 |

71 |

42 |

|

58 |

Zipper Attach (L) |

SNLS |

0.75 |

80 |

48 |

|

59 |

Zipper Marking |

Manual |

0.30 |

200 |

120 |

|

60 |

Zipper Attach (R) |

SNLS |

0.75 |

80 |

48 |

|

61 |

Zipper Piping Attach |

SNLS |

0.95 |

63 |

38 |

|

62 |

Piping Tack |

SNLS |

0.30 |

200 |

120 |

|

63 |

Zipper Top Stitch(L) |

SNLS |

0.70 |

86 |

51 |

|

64 |

Zipper Top Stitch(R) |

SNLS |

0.70 |

86 |

51 |

|

65 |

Final Trimming |

Manual |

0.75 |

80 |

48 |

|

|

Total |

|

39.54 |

|

|

In the above table a short name of sewing machines is written. Followings are the abbreviation of those short machine codes.

SNLS - Single needle lock stitch

3T O/L - 3 Thread over lock

Manual - Helper

How to set the target per hour in the Sewing line of the Garment Factory?

Formula to set the 100% target:

Daily Target = (Worker x Working hour x 60/ SMV) x efficiency %

Basic Pitch Time (BPT) =Total SMV / Total Manpower.

Fabric Types and Needle Size Chart:

|

Fabric Types |

Needle Size |

|

Very fine fabrics (silk, chiffon,

organza, voile, lace) |

8, 9, 10 |

|

Light weight fabrics (cotton,

heavier silks, synthetics, spandex, lycra) |

11, 12 |

|

Medium weight fabrics (velvet,

fine corduroy, linen, muslin, tricot, knits, fleece) |

14 |

- Operation Breakdown of Ladies Fake Down Vest Jacket

- Operation Breakdown of Boys Rain Jacket

- Operation Breakdown of Loose Padding Jacket

- What is the SMV of Puffer Vest?

- Operation Breakdown of Hoodie Vest

- Operation Bulletin of Vest

- Operation Bulletin of Flannel Jacket (Padded)

- Operation Breakdown and SMV of Jacket (Padded Softshell)

- Operation Bulletin of Denim Jacket (Men)

- What is operation breakdown in the garment industry?

“Wear a mask to save lives. Clean your hands. Keep at a safe distance.”

Thank you so mach

ReplyDelete