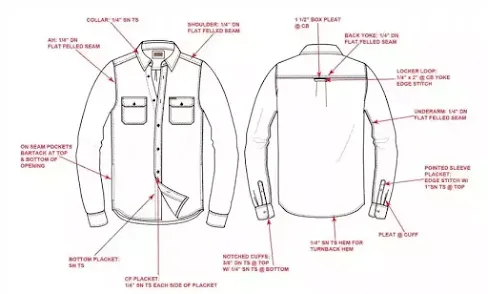

Operation Bulletin of a Flannel Shirt

|

SL. |

Operation |

Type of Machine |

SMV |

Target 100% |

Target 65% |

|

Collar Cuff &

Make |

|||||

|

1 |

Collar & Collar

Band & Cuff Fusing |

Helper |

0.50 |

120 |

78 |

|

2 |

Collar Mark |

Helper |

0.25 |

300 |

195 |

|

3 |

Collar Sewing |

SNLS |

0.40 |

133 |

87 |

|

4 |

Collar Edge Cut &

Turn |

3T O/L |

0.30 |

200 |

130 |

|

5 |

Collar Top Stitch 1/4 |

SNLS |

0.45 |

133 |

87 |

|

6 |

Collar Band Rolling |

SNLS |

0.30 |

200 |

130 |

|

7 |

Collar Band No. Match |

Helper |

0.25 |

240 |

156 |

|

8 |

Collar Band Attach |

SNLS |

0.50 |

120 |

78 |

|

9 |

Collar Band Top Stitch |

SNLS |

0.40 |

150 |

98 |

|

10 |

Collar Finishing (Edge

Cut) |

3T O/L |

0.35 |

171 |

111 |

|

11 |

Cuff Rolling |

SNLS |

0.30 |

200 |

130 |

|

12 |

Cuff Marking |

Helper |

0.30 |

200 |

130 |

|

13 |

Cuff Sewing |

SNLS |

0.45 |

133 |

87 |

|

14 |

Cuff edge Cut

&Turn |

Helper |

0.40 |

150 |

98 |

|

15 |

Cuff 1/4 Top Stitch |

SNLS |

0.50 |

120 |

78 |

|

Sleeve Make |

|||||

|

16 |

Placket Placement Mark

& Cut |

Helper |

0.30 |

200 |

130 |

|

17 |

Gamble Attach |

SNLS |

0.35 |

171 |

111 |

|

18 |

Gamble Tack & Raw

Edge Cut |

SNLS |

0.30 |

200 |

130 |

|

19 |

Placket No. Match |

Helper |

0.30 |

200 |

130 |

|

20 |

Placket Iron |

Iron |

0.65 |

92 |

60 |

|

21 |

Placket Attach |

SNLS |

0.70 |

86 |

56 |

|

Back Part |

|||||

|

22 |

Dart Tack |

SNLS |

0.30 |

200 |

130 |

|

23 |

Hanger Loop Make &

Attach |

SNLS |

0.35 |

171 |

111 |

|

24 |

Main Label Facing Iron |

Helper |

0.30 |

200 |

130 |

|

25 |

Label Attach At Facing |

SNLS |

0.30 |

200 |

130 |

|

26 |

Facing Attach At Back

Yoke |

SNLS |

0.30 |

200 |

130 |

|

27 |

Back Yoke No Match |

Helper |

0.30 |

200 |

130 |

|

28 |

Back Yoke Attach |

5T O/L |

0.30 |

200 |

130 |

|

29 |

Back Yoke Top Stitch |

DNCS |

0.30 |

200 |

130 |

|

Front Part |

|||||

|

30 |

Facing Attach At Pocketing

|

SNLS |

0.30 |

200 |

130 |

|

31 |

Pocket Bag OL |

3T O/L |

0.60 |

100 |

65 |

|

32 |

Pocket Bag Top Stitch |

SNLS |

0.60 |

100 |

65 |

|

33 |

Pocketing Attach At

Side Pocket Place & Conner Cut |

SNLS |

0.60 |

100 |

65 |

|

34 |

Side Pocket Opening

Top Stitch |

SNLS |

0.50 |

120 |

78 |

|

35 |

Side Pocket Tack |

SNLS |

0.30 |

200 |

130 |

|

36 |

Pair Tack |

SNLS |

0.30 |

200 |

130 |

|

37 |

Top Center Rolling |

MNCS |

0.35 |

200 |

130 |

|

38 |

Side Pocket Attach At Top Center |

SNLS |

0.35 |

171 |

111 |

|

39 |

Top center Rolling |

SNLS |

0.45 |

133 |

87 |

|

40 |

Top center Iron |

Heat Seal |

0.30 |

200 |

130 |

|

41 |

Front Pocket Placement

Mark |

Helper |

0.40 |

150 |

98 |

|

42 |

Pocket Check Match |

Helper |

0.40 |

150 |

98 |

|

43 |

Pocket Marking |

Helper |

0.35 |

171 |

111 |

|

44 |

Pocket Fitting |

3T O/L |

0.35 |

171 |

111 |

|

45 |

Pocket Rolling |

SNLS |

0.40 |

150 |

98 |

|

46 |

Pocket Iron |

Iron |

0.65 |

92 |

60 |

|

47 |

Front Pocket Attach |

SNLS |

0.65 |

92 |

60 |

|

48 |

Front Pocket 1/4 Top Stitch |

SNLS |

0.40 |

150 |

98 |

|

49 |

Flap Check &

Number Match |

Helper |

0.35 |

171 |

111 |

|

50 |

Flap Fusing |

Steam Iron |

0.30 |

200 |

130 |

|

51 |

Flap Mark & Sewing |

Pattern Sewer MC |

0.45 |

150 |

98 |

|

52 |

Flap Raw edge Cut

&turn |

3T O/L |

0.40 |

150 |

98 |

|

53 |

Flap Top Stitch |

SNLS |

0.35 |

171 |

111 |

|

54 |

Flap 1/4 Top Stitch |

SNLS |

0.35 |

171 |

111 |

|

55 |

Flap Edge Cut &

Sewing |

DLM |

0.30 |

200 |

130 |

|

56 |

Flap Attach |

SNLS |

0.40 |

150 |

98 |

|

57 |

Flap Top Stitch |

SNLS |

0.30 |

200 |

130 |

|

58 |

Patch Label Attach |

SNLS |

0.30 |

200 |

130 |

|

59 |

Front Fitting |

Helper |

0.30 |

200 |

130 |

|

Assemble |

|||||

|

60 |

Front & Back No

Match |

Helper |

0.30 |

200 |

130 |

|

61 |

Shoulder Join |

SNLS |

0.60 |

100 |

65 |

|

62 |

Shoulder Top Stitch |

DNLS |

0.30 |

200 |

130 |

|

63 |

Collar Mark |

Helper |

0.25 |

240 |

156 |

|

64 |

Collar No Match &

Mark |

Helper |

0.30 |

200 |

130 |

|

65 |

Collar Attach |

SNLS |

0.55 |

109 |

71 |

|

66 |

Collar Top Stitch &

Size Label Attach |

SNLS |

0.60 |

86 |

56 |

|

67 |

Sleeve No Match &

Mark |

Helper |

0.30 |

171 |

111 |

|

68 |

Sleeve Attach |

5T O/L |

0.60 |

92 |

60 |

|

69 |

Arm Hole Top Stitch |

DNCS |

0.60 |

92 |

60 |

|

70 |

Care Label Attach |

SNLS |

0.30 |

200 |

130 |

|

71 |

Side Seam Join |

3T O/L |

0.75 |

86 |

56 |

|

72 |

Side Seam Top Stitch |

FOA |

0.60 |

100 |

65 |

|

73 |

Cuff No Match

& Mark |

Helper |

0.45 |

133 |

87 |

|

74 |

Cuff attach |

SNLS |

0.50 |

100 |

65 |

|

75 |

Bottom Rolling |

SNLS |

0.60 |

100 |

65 |

|

76 |

All Button Hole |

BH |

0.80 |

75 |

49 |

|

77 |

All Bartack |

B/T |

0.50 |

120 |

78 |

|

78 |

Thread Cut |

Helper |

0.60 |

100 |

65 |

|

|

Total |

|

32.25 |

|

|

Full form of Machine Name:

How Flap Sewing with a Pattern Sewer Machine Reduces Marking Helpers and Cost:

Please see the video below -

1: Traditional Method

Show a worker manually marking and sewing flaps.

Explain:

"In traditional methods, marking each flap manually requires extra helpers, time, and effort."

2: Using Pattern Sewer Machine

Show the pattern sewer machine stitching the flap directly onto the fabric.

Explain:

"With a pattern sewer machine, the stitching is precise and automated, eliminating the need for manual marking helpers."

3: Benefits Highlight

Display close-up shots of the machine working smoothly.

Bullet points appear on the screen:

"Reduces labor costs"

"Speeds up production"

"Ensures uniformity and quality"

Summary:

By adopting the pattern sewer machine for flap sewing, manufacturers can save time, reduce costs, and improve product quality. It's a smart move for efficient production.Thank you for your patience reading. Please, Share this article with others. It will inspire me to write more about this.

“Wear a mask to save lives. Clean your hands. Keep at a safe distance.”

Hi, Shorab,

ReplyDeleteThis is a great post for the Industrial Engineering (IE) of Garment. It will help them to understand and prepare the layout. Please keep it up. All your hard work is much appreciated.

Thanks

Thanks

DeleteI have read your blog. It is helpful post. Keep it up.

ReplyDeleteHelpful post for IE. Keep writing

ReplyDeleteThanks

Nice blog. Keep writing

ReplyDeleteThanks

Good job sir.this blog may help all ie

ReplyDelete